Shop Finds Jobs Using Online Marketplace

TD&M Machining LLC wanted to grow its business without competing against other local shops. After subscribing to MFG.com, about 75 percent of the shop’s customers now originate from the platform.

Case Study Post: 9/1/2017 Modern Machine Shop, Julia Hider, Assistant Editor

Competition among jobs shops for work can be fierce. This is especially true for shops like TD&M Machining LLC of Dubuque, Iowa—a town in which there are many machine shops within a 50-mile radius and “everybody knows everybody,” says founder Troy Donath. Because of that, he decided to see if he could find work via the internet. After winning jobs through an online manufacturing marketplace, Mr. Donath has been able to grow his business for the past 10 years without competing against his immediate neighbors.

In 2007, Mr. Donath started TD&M with a two-axis manual machine in his garage. He began taking on work part time as it suited his availability, with the long-term goal of becoming his own boss. When he was laid off from his full-time job at the end of 2008, he needed to quickly grow his business to support his family. This was challenging, however, as his fledgling job shop did not have the resources to hire a sales staff, and he did not have the desire to compete for local work. “Shop owners do not take kindly to other shops trying to solicit their customers,” he says. “I didn’t want to get involved in this competitive environment, so I decided to seek work from outside the area.”

To remedy this, he searched the term “outsourced machine parts” on the internet and found MFG.com, an online manufacturing marketplace designed to bring together buyers and sellers from across the globe. Mr. Donath subscribed TD&M to the platform as a supplier and created a profile, specifying processes and geographic regions with which his company could work. On the other end of the platform, buyers upload requests for quotes (RFQs), including all relevant engineering drawings, which are reviewed by MFG.com staff to ensure completeness and accuracy.

Mr. Donath can filter RFQs using categories such as materials, part size and run size to find jobs on which to bid. With parameters in place, the platform sends him email notifications when RFQs match those specifications. Mr. Donath uses the platform to bid on jobs, and the buyer can either award the job via the platform or offline. Suppliers and buyers, like Mr. Donath and some of his clients, often work outside the platform to reach a deal. “Once I do a job and they like it, we deal offline,” he says.

The platform offers a rating system for both types of users to assist buyers in selecting suppliers and help suppliers decide with whom to work. It also provides suppliers with other data on buyers, including the number of RFQs posted in the last two years, the percentage of bids awarded on the platform, the total dollars awarded over the last two years and the average dollar value of each award.

Although he is not competing for local work, one of the major benefits of this global platform for Mr. Donath is that it provides a much larger pool of potential customers. According to MFG.com, more than 2,000 buyers sourced more than 9,000 parts on the platform in 2016. “Using MFG.com is like having a salesperson on staff working for you 24/7. Every day, it identifies work for my consideration and allows me to bid on those jobs that match our skill sets,” Mr. Donath says.

Another advantage is that he can use it as he needs it. “If I get busy and don’t need new work, I won’t look at MFG.com for a while,” he says. “I don’t have to constantly quote all the time. But, if I see a drop in work, I get back on and pick up another customer.”

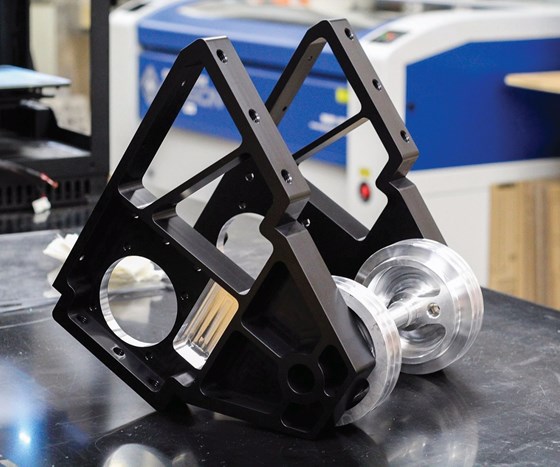

Mr. Donath says the investment he made in the subscription paid off as he landed reliable clients. “They didn’t care that I was working out of my garage, as long as the parts were good,” he says. Since landing its first two customers on MFG.com, TD&M has grown from a one-man, one-machine operation in a garage to a business with the equivalent of five and a half full-time employees running six CNC machines in a 1,000-sqaure-foot facility. Most of the company’s business is job-shop-type work, with one-time projects commonly consisting of one to five parts. “We basically do whatever comes in the door,” he says. For example, TD&M makes small aluminum pieces for a company that manufactures and sells splicing, stripping and cleaning machines for the fiber-optics sector. It also machines parts for a road-construction company that builds scrapers to retrofit with articulating trackers.

Most of his experiences working with buyers have been positive, Mr. Donath says, and some have been memorable. For instance, he saw parts up for bid from the Massachusetts Institute of Technology. “I was a bit skeptical, but submitted a quote nonetheless,” he says. Eventually, a student called to discuss the parts, which were necessary for a robot for the television show “BattleBots,” in which competitors build robots and fight them in an elimination tournament. “MIT sent me pictures showing me the location of the parts I machined,” he says. “It was pretty exciting.”

According to Mr. Donath’s estimates, he has gotten more than 100 jobs from the platform. Many have become repeat customers who now work with him outside of the platform. He estimates that 75 percent of the company’s existing customers came from MFG.com, and four or five make up most of the revenue.

He says that he plans to continue using MFG.com to find more long-term customers. He also recognizes that the industry can be unpredictable, a lesson he learned when one of his first clients took its work in house. “You never know what life holds,” he says, “but I know I can always count on MFG.com for the work my shop needs.”

When Troy Donath was laid off from his full-time job in 2008, he had to quickly grow his job shop to support his family. He used MFG.com to find small, one-time projects.

Mr. Donath did not want to compete for work that was local to his shop in Dubuque, Iowa. MFG.com enabled him to find jobs from all over the country, including this piece he made for the Massachusetts Institute of Technology.

The piece Mr. Donath made for MIT was part of a robot, shown here, that students were making for the television show “BattleBots.”

——————————————————————————————————–

Case Study Post: 9/1/2017 Modern Machine Shop, Julia Hider, Assistant Editor

Click Here for a free subscription to Modern Machine Shop magazine.

Click Here to subscribe to the MMS Extra monthly e-newsletter.

This article is reprinted with permission from Modern Machine Shop Magazine, and is protected under U.S. and international copyright laws. Modern Machine Shop Magazine is protected under U.S. and international copyright laws. Before reproducing anything from this Web site, call Gardner Business Media, Inc. (513) 527-8800.