A Walker Ceramax 6x12 has come my way and I need to take it apart. Cam failure is the suspect. I have seen PM discussions on disassembly of the permanent magnet chucks but have not found one specific to the Walker. Anyone know where to look on PM? Anyone taken a walker apart and successfully repair the cam?

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with Walker Ceramax 6x12 dissambly

- Thread starter mach2

- Start date

- Replies 12

- Views 6,538

Bill in PA

Hot Rolled

- Joined

- Jan 25, 2011

- Location

- Fairfield, PA

I have repaired mine. Here is a link to the Walker page where you can download a repair sheet:

Workholding Magnet - Permanent Magnetic Grinding Chuck - Ceramax - Walker Magnetics

I made a new cam for mine as well as boring and sleeving the housing for the handle shaft. I put an o-ring in the sleeve so the oil does not leak out. I used the old cam as a pattern and made the new one oversize and ground it to fit.

Straight-forward repairs from what I remember. Take precautions so you don't pinch your fingers between the magnet and the top plate.

Bill

Workholding Magnet - Permanent Magnetic Grinding Chuck - Ceramax - Walker Magnetics

I made a new cam for mine as well as boring and sleeving the housing for the handle shaft. I put an o-ring in the sleeve so the oil does not leak out. I used the old cam as a pattern and made the new one oversize and ground it to fit.

Straight-forward repairs from what I remember. Take precautions so you don't pinch your fingers between the magnet and the top plate.

Bill

split tenth

Hot Rolled

- Joined

- Sep 19, 2007

- Location

- mesa arizona

Heed what Bill said.That magnet is very powerfull and could pinch off your fingertips in a split second.

Toms Wheels

Titanium

- Joined

- Dec 30, 2005

- Location

- Jersey Shore

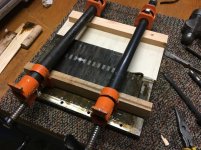

The magnets are very strong, I worked on an 18" same model. Impossible to slide the magnet off by hand. After removing the top plate from the body, place the plate face down on a table, clamp the long edge to the table one side, on the other place a 1x8 and clamp that to the table. Now use long reach clamps from the 1x8 to the far side of the magnet to slide it off the top plate. It will be surprisingly difficult to slide the magnet.

Top came off without a hitch.

I may be using that advise for sliding the magnet off. Chuck is apart and magnet still stuck to the underside of the chuck top.

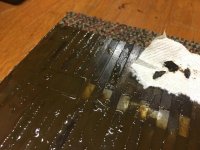

Internal inspection reveals a broken leaf spring and what appears to be one magnet section broken (fractured). Cam looks in great shape.

Prior to disassembly I checked the strength. Very good on one end and marginal on the other.

I'm thinking to slide the internal magnet off the top to have a look at the other side of the fractured magnet section, and clean the surfaces at the least.

Any suggestions at this point are welcome. Thanks all.

I may be using that advise for sliding the magnet off. Chuck is apart and magnet still stuck to the underside of the chuck top.

Internal inspection reveals a broken leaf spring and what appears to be one magnet section broken (fractured). Cam looks in great shape.

Prior to disassembly I checked the strength. Very good on one end and marginal on the other.

I'm thinking to slide the internal magnet off the top to have a look at the other side of the fractured magnet section, and clean the surfaces at the least.

Any suggestions at this point are welcome. Thanks all.

ballen

Diamond

- Joined

- Sep 25, 2011

- Location

- Garbsen, Germany

.Any suggestions at this point are welcome.

Not quite what you had in mind, but my suggestion is, post some photos. I think that will get you lots of other suggestions and support along the lines of what you are asking for.

Toms Wheels

Titanium

- Joined

- Dec 30, 2005

- Location

- Jersey Shore

I believe that that is the spacer not the magnet. There is some kind of epoxy that glues this together. Is a group of bars separated from the rest, or just those chips.

You need to get the magnet off the top plate, inspect the surface, check if the epoxy has swelled due to oil reaction, or rust between the surfaces. A no-name chuck had the epoxy swell so much it was useless, ground off the swelled stuff, worked much better, not near as good as the walker.

Call walker and ask them.

You need to get the magnet off the top plate, inspect the surface, check if the epoxy has swelled due to oil reaction, or rust between the surfaces. A no-name chuck had the epoxy swell so much it was useless, ground off the swelled stuff, worked much better, not near as good as the walker.

Call walker and ask them.

I believe that that is the spacer not the magnet. There is some kind of epoxy that glues this together. Is a group of bars separated from the rest, or just those chips.

You need to get the magnet off the top plate, inspect the surface, check if the epoxy has swelled due to oil reaction, or rust between the surfaces. A no-name chuck had the epoxy swell so much it was useless, ground off the swelled stuff, worked much better, not near as good as the walker.

Call walker and ask them.

You are correct. It is the epoxy between the magnets that have failed. Good news is chips in the epoxy are on the bottom. Top of the magnet looks good but there was a lot of debris in the epoxy grooves. Also some swelling of the epoxy. I'm thinking to surface the epoxy, but with what?

I'm going to clean it up, do something about the leaf spring, put it back together and see if there is improvement.

Is gear oil acceptable? How much oil?

More photos in a moment.

Bill in PA

Hot Rolled

- Joined

- Jan 25, 2011

- Location

- Fairfield, PA

You are correct. It is the epoxy between the magnets that have failed. Good news is chips in the epoxy are on the bottom. Top of the magnet looks good but there was a lot of debris in the epoxy grooves. Also some swelling of the epoxy. I'm thinking to surface the epoxy, but with what?

I'm going to clean it up, do something about the leaf spring, put it back together and see if there is improvement.

Is gear oil acceptable? How much oil?

More photos in a moment.

I used gear oil (80W I think) but I cannot remember where I read that gear oil is what's called for. I filled mine to the top.

Bill

M.B. Naegle

Diamond

- Joined

- Feb 7, 2011

- Location

- Conroe, TX USA

I can't speak to the disassembly of one, but we sent ours back to Walker a few years ago and it came back looking and working just like new (to the tune of a little over $1000). Our's was probably 40 years old and the mechanical part of it was well worn, but they saved it.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 1

- Views

- 445