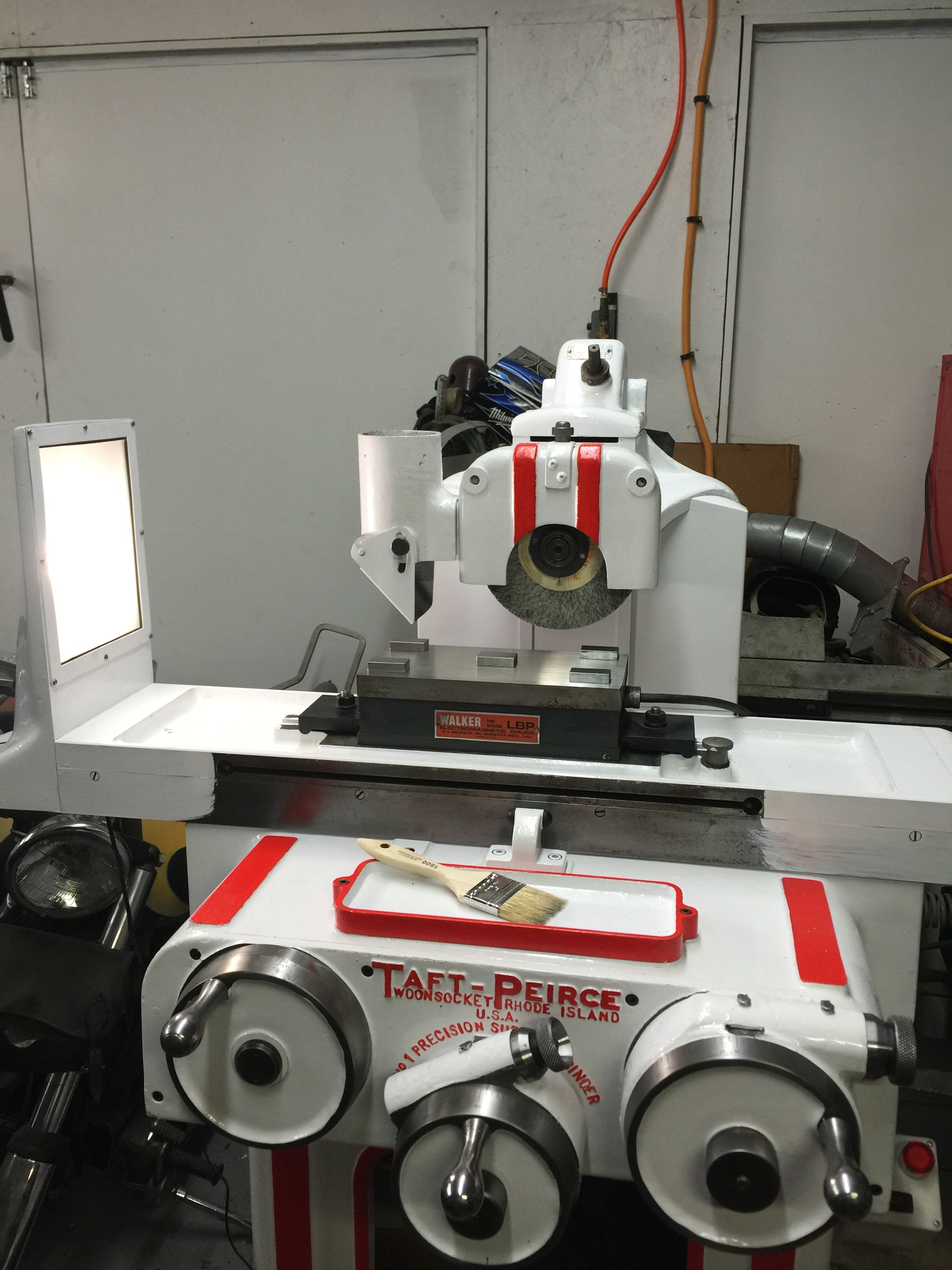

Edwin, I find that interesting to me as I had rebuilt this one, myself. It was quite the learning experience. I really came to respect the men that designed and built them. I believe I posted about it, but I rebuilt the whole thing, top to bottom, and in the process ended up having to MAKE the cross travel bearings as there were none of the proper size available anywhere that was checked. I was very concerned and worried for how it would work out and it turns out that I was concerned for no good reason. The bearings turned out great and the grinder's operation even more wonderful. Having so many in one place while they were used, I have to wonder if you were ever witness to any obvious flaws or shortcoming in these old girls? Any common gripes between the grindhands, about them? Thanks.