Forrest Silas

Aluminum

- Joined

- Mar 31, 2005

- Location

- Clanton Alabama

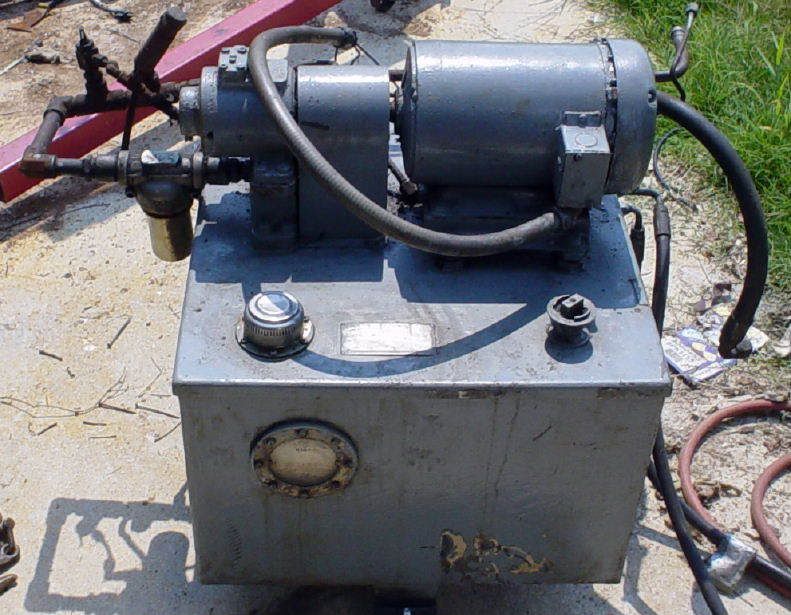

I recently dragged home a tired old Norton 6X18 surface grinder. I have never seen a surface grinder in operation, and know very little about grinding, so I will probably have quite a few questions in the weeks to come. Right now I am waiting for a manual to arrive from another member, so I can figure out how to connect all the hydraulic lines.

In the mean time I need to start gathering the basic tooling, which leads to my first question. I can't afford a new USA made magnetic chuck. I have found several imported 6X18 chucks for around $250. Also I see used USA chucks selling on EBay for the same money or less. What would cause me to regret buying the imported chuck? In other words, what are the deficiencies of the import vs used USA?

Thanks,

Forrest

In the mean time I need to start gathering the basic tooling, which leads to my first question. I can't afford a new USA made magnetic chuck. I have found several imported 6X18 chucks for around $250. Also I see used USA chucks selling on EBay for the same money or less. What would cause me to regret buying the imported chuck? In other words, what are the deficiencies of the import vs used USA?

Thanks,

Forrest

since I could grind the top when I mounted it on the machine. I was hoping to avoid the frustrations of searching for a quality used one on EBay.

since I could grind the top when I mounted it on the machine. I was hoping to avoid the frustrations of searching for a quality used one on EBay.

If I find a 6X12 first that fits my budget I'll buy it.

If I find a 6X12 first that fits my budget I'll buy it.