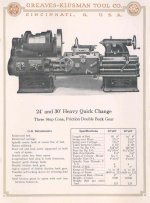

Good morning All. I've spend a fair amount of time researching lathes in general but these old belt driven units are a bit harder for me to find information for. I'm not a machinist by trade, and barely hobby, so therefore I'm not very familiar with the machine past my basic knowledge. What I'm looking for is general information on the unit, I'll assume hoping for a manual is laughable at best.

I'm also curious about the availability of things such as tool holders, chucks for the tailstock, live centers, a lathe mill attachment, etc. I'm not sure if the ways are a standard dimension so the interchanging of parts from other lathes would be an option?

The issue with my current tool holders (I have 2 and they're mirror images of each other) is it's not perpendicular to the center of the chuck, they angle upward at what looks like a ~20* angle.

I'll assume the taper in the tailstock is just a morse taper?

I'm also curious about the availability of things such as tool holders, chucks for the tailstock, live centers, a lathe mill attachment, etc. I'm not sure if the ways are a standard dimension so the interchanging of parts from other lathes would be an option?

The issue with my current tool holders (I have 2 and they're mirror images of each other) is it's not perpendicular to the center of the chuck, they angle upward at what looks like a ~20* angle.

I'll assume the taper in the tailstock is just a morse taper?