I'm currently sitting on two big lathes. Both are projects and both are probably beyond my abilities or at least time available to get running.

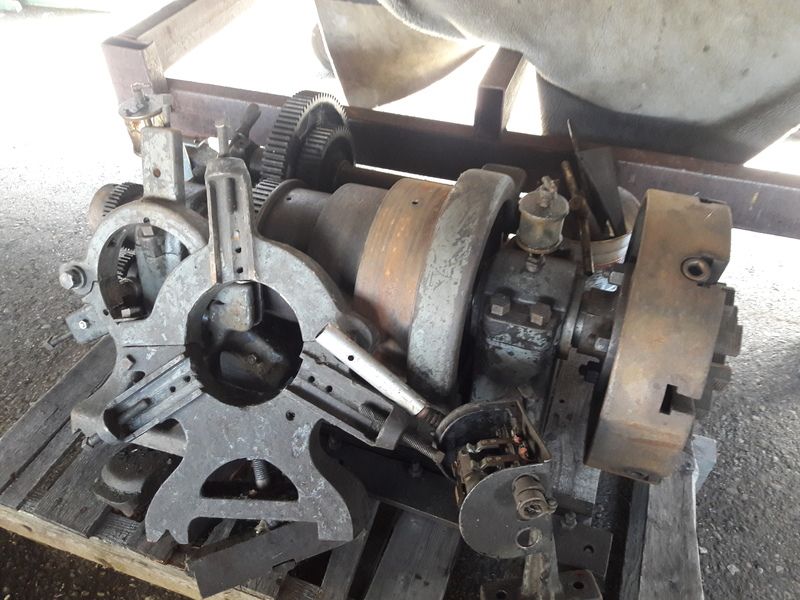

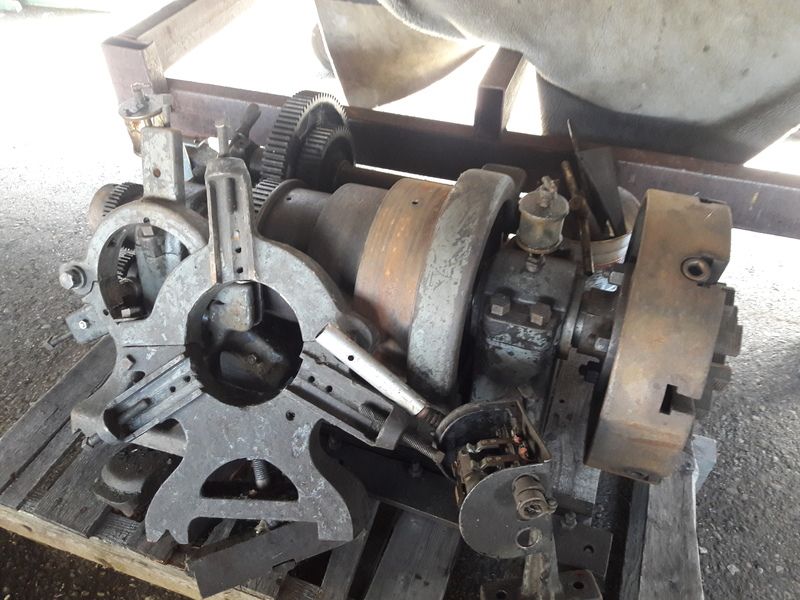

I just came across this ATW lathe. It is probably a better candidate for my shop. Most things appear to be intact. It has a double back gear, a gearbox, and an over-arm motor mount for the countershaft. Known problems are as follows:

1. Tailstock spindle is stuck. I can soak it and get it free.

2. There are few chipped gear teeth. One on the larger of the two back gears.

3. There is a bit of play in the index lever of the gearbox. I imagine this just needs a new bushing. See attached video.

4. One of the two knobs on the apron has been brazed back together. I don't know what that knob does so I'm not sure what caused the break.

5. I think these lathes had a cover over the gears on the back of the headstock. If so, it is missing. I can fabricate one.

6. The lathe is in parts so it is hard to assess the whole machine.

Other than that, it looks that gear teeth are not badly worn, the feed screw is in good shape.

The owner intended to sell for industrial furnishings. I think I may offer my 20" Leblond gap bed lathe in trade. He can sell the legs and make more money off of scrap since the lathe is much heavier. I hate to send any of these beasts to such a fate, but the gap bed is way too much lathe for me.

I just came across this ATW lathe. It is probably a better candidate for my shop. Most things appear to be intact. It has a double back gear, a gearbox, and an over-arm motor mount for the countershaft. Known problems are as follows:

1. Tailstock spindle is stuck. I can soak it and get it free.

2. There are few chipped gear teeth. One on the larger of the two back gears.

3. There is a bit of play in the index lever of the gearbox. I imagine this just needs a new bushing. See attached video.

4. One of the two knobs on the apron has been brazed back together. I don't know what that knob does so I'm not sure what caused the break.

5. I think these lathes had a cover over the gears on the back of the headstock. If so, it is missing. I can fabricate one.

6. The lathe is in parts so it is hard to assess the whole machine.

Other than that, it looks that gear teeth are not badly worn, the feed screw is in good shape.

The owner intended to sell for industrial furnishings. I think I may offer my 20" Leblond gap bed lathe in trade. He can sell the legs and make more money off of scrap since the lathe is much heavier. I hate to send any of these beasts to such a fate, but the gap bed is way too much lathe for me.