Dr. Strangemill

Plastic

- Joined

- Oct 31, 2017

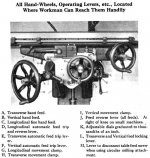

Hi,I am the recent owner of a Brown and Sharpe No. 2 milling machine. I'm looking for as much info as possible. This mill was passed down from father to son, then bought by a local enthusiast about 10 years ago (the son was about 70 at the time), and finally by me this past weekend. From what I gather, instead of a patent date, it has "Patent Pending" cast onto the side. I see the raised flat part under the support arm that a serial number may have been stamped on, but the paint/grease is so thick, it is unreadable. There is, however, a serial number stamped on the front of the supporting arm of 565.

What I'm looking for is a date range to this machine, any and all info about it, including original color and specs.

Attached to it is also a Rusnok Vertical milling head, obviously added later as an upgrade. Any info in that would be welcome as well.

I basically stumbled on this listing, went to see the machine and fell in love with the way it looks, so I bought it all, tooling and VFD included for $650.

What I'd love to do is restore it, and possibly convert it to a cnc, or is that sacrilege??

PS, sorry for the sideways images. Can't seem to be able to edit and rotate them.

What I'm looking for is a date range to this machine, any and all info about it, including original color and specs.

Attached to it is also a Rusnok Vertical milling head, obviously added later as an upgrade. Any info in that would be welcome as well.

I basically stumbled on this listing, went to see the machine and fell in love with the way it looks, so I bought it all, tooling and VFD included for $650.

What I'd love to do is restore it, and possibly convert it to a cnc, or is that sacrilege??

PS, sorry for the sideways images. Can't seem to be able to edit and rotate them.