Panza

Stainless

- Joined

- Oct 23, 2005

- Location

- Lillehammer, Norway

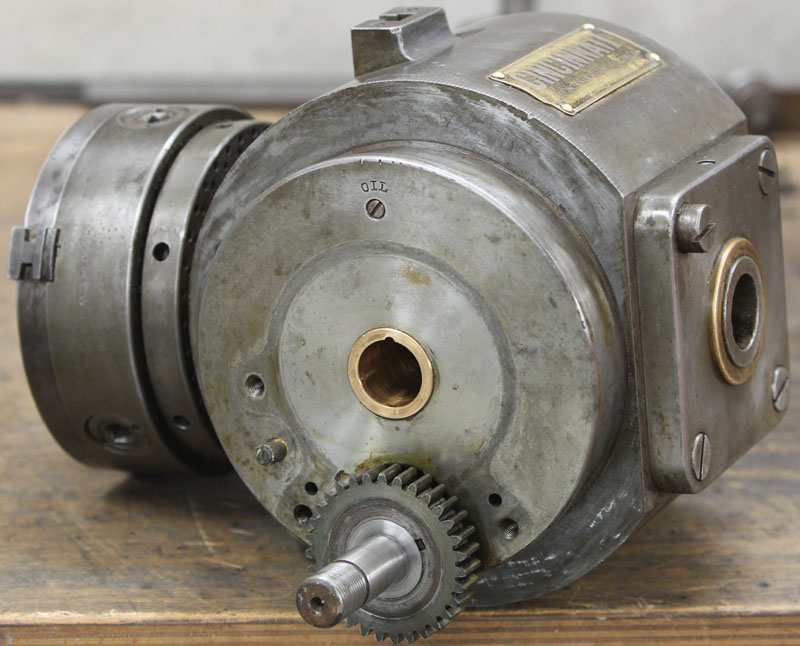

I'm trying to take apart my new old Cincinnati dividing head due to a tight spot in one place on the worm gear (every 40th revolution).

I've taken it down the the main casting but how do I get the worm and gear out ?

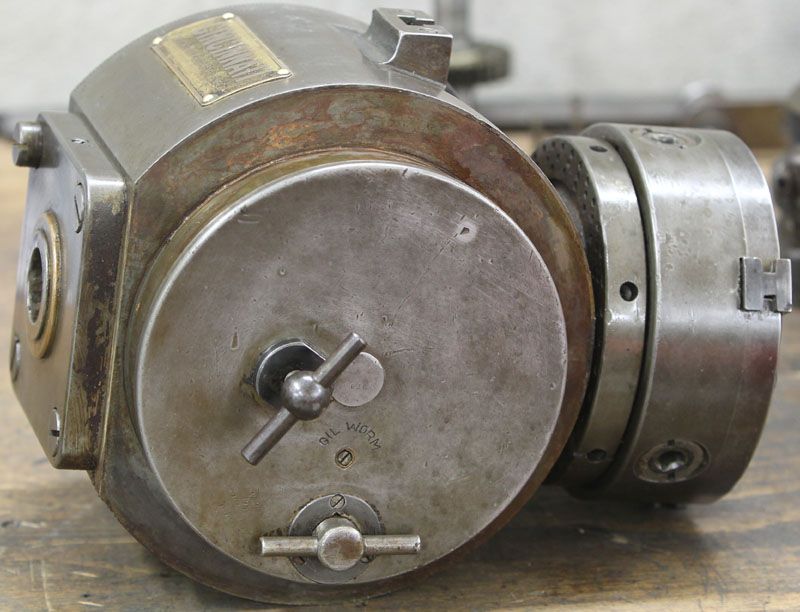

Before that I need access to the worm gear to lock it in place to get the chuck off. That chuck has been on there for 50 years I bet.

I've taken it down the the main casting but how do I get the worm and gear out ?

Before that I need access to the worm gear to lock it in place to get the chuck off. That chuck has been on there for 50 years I bet.