cb1

Cast Iron

- Joined

- Jul 16, 2015

All,

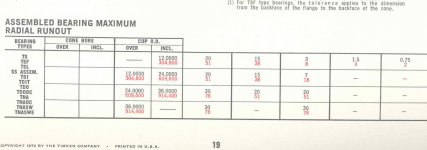

Taking apart my Clausing Dual and wondering if this is a special bearing. Went through the Timken catalog, but not sure what I am reading. The bearing is marked Timken - x with a number 14125. I have not pulled a race yet as I will have to use to "welding trick" to get them out and that will most definitely ruin them.

Also, if anyone knows the v-belt number for the Clausing 100 series lathes, that would be great. Mine has a raggedy make a belt which is showing its date.

Some pictures of my project.

Thanks,

cb1

Taking apart my Clausing Dual and wondering if this is a special bearing. Went through the Timken catalog, but not sure what I am reading. The bearing is marked Timken - x with a number 14125. I have not pulled a race yet as I will have to use to "welding trick" to get them out and that will most definitely ruin them.

Also, if anyone knows the v-belt number for the Clausing 100 series lathes, that would be great. Mine has a raggedy make a belt which is showing its date.

Some pictures of my project.

Thanks,

cb1