Paolo_MD

Stainless

- Joined

- Apr 6, 2013

- Location

- Damascus, MD

A person near Chestertown (Maryland Eastern Shores) recently donated a few machines to Tuckahoe.

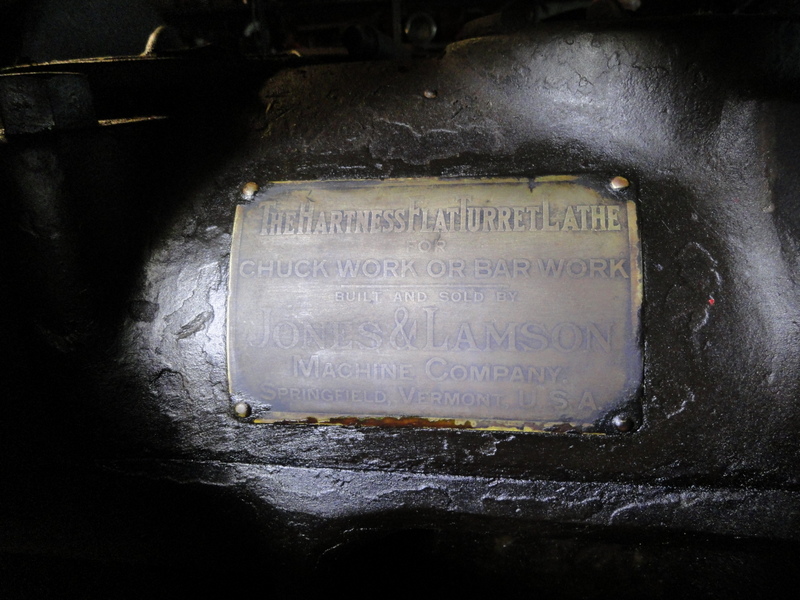

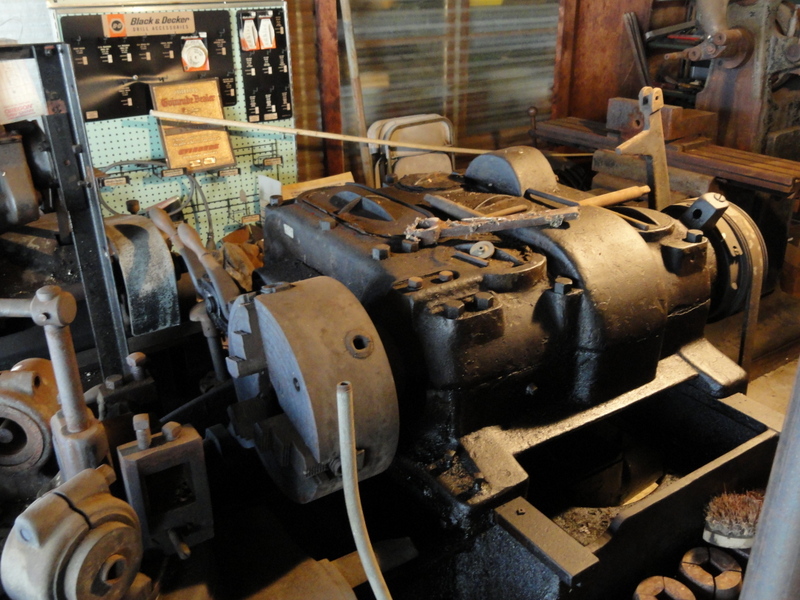

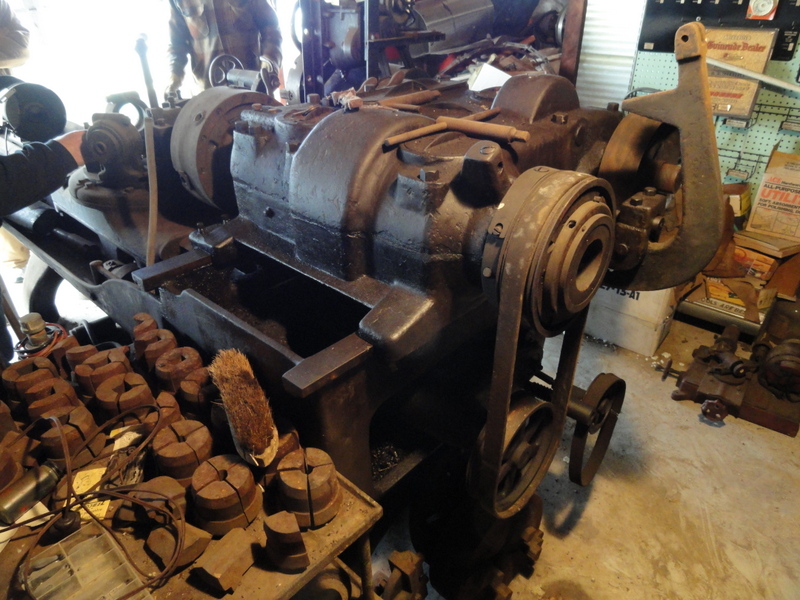

At the farm there is still a fairly large machine well deserving to be saved: a Hartness Flat Turret Lathe built by Jones and Lamson Machine Company.

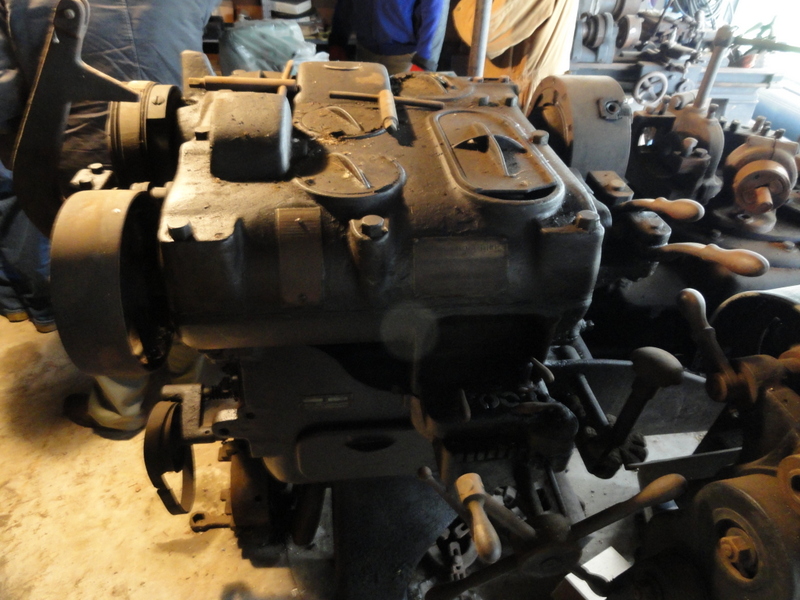

This lathe is fairly big, weighting no less than 7-8000lb, possibly even over 10000lb. It's well equipped with chuck and collets, and from a cursory inspection, it looks like in very good shape and we couldn't find anything broken. Unfortunately, at Tuckahoe we are running out of space and would end up in the field covered with tarps.

It deserves much better treatment than that.

If nobody comes to the rescue of this machine, the owner will soon break it in more manageable chunks and sell it for scrap. As he has donated the other machines to Tuckahoe, he is willing to donate this one to any other non-profit institution that is willing to take care of it.

Unfortunately, when I was there, the space was scrammed with other machines and there was not enough room for taking more decent pictures and I'm still waiting for better pictures from the son of the owner.

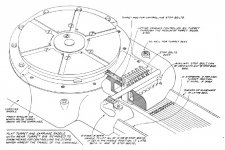

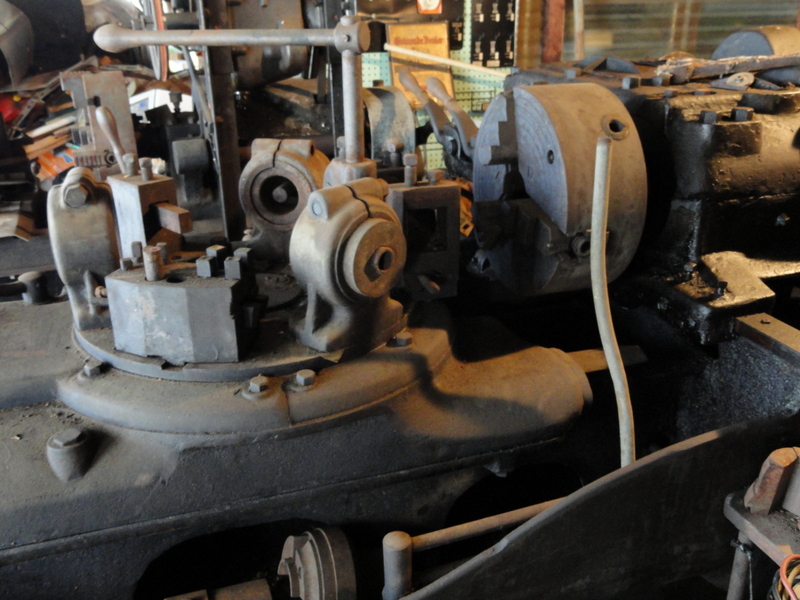

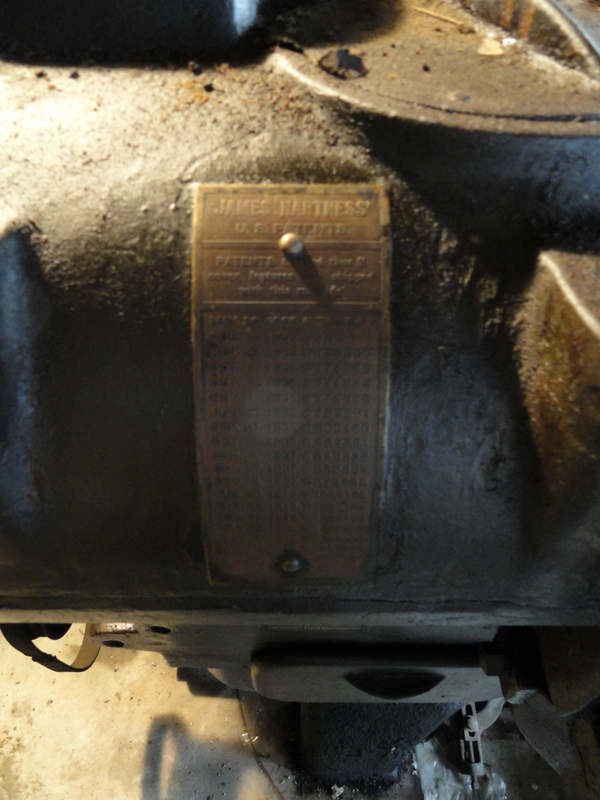

A distinctive peculiarity of this lathe is the flat turret: Mr Hartness invented this style of turret with the height lower than the spindle axis, so that long stock could be accommodated. He patented and, at the beginning of the 1900, he was receiving $100 in royalties for each of these lathes sold.

Another interesting feature is that the whole headstock can translate side-wise, while keeping all the mechanical connections with all the feeds.

Lastly, another distinctive feature of this lathe is the system of stops for the turret: rectangular bars between the ways, clamped at the tailstock side:

Here you can find the manual for this lathe

Even if you are unable to rescue it yourself, please, forward the link to this thread to anybody who could be interested. We would really hate to see it chopped to pieces.

Of course, if you're interested, send me a private message.

Thanks!

Paolo

At the farm there is still a fairly large machine well deserving to be saved: a Hartness Flat Turret Lathe built by Jones and Lamson Machine Company.

This lathe is fairly big, weighting no less than 7-8000lb, possibly even over 10000lb. It's well equipped with chuck and collets, and from a cursory inspection, it looks like in very good shape and we couldn't find anything broken. Unfortunately, at Tuckahoe we are running out of space and would end up in the field covered with tarps.

It deserves much better treatment than that.

If nobody comes to the rescue of this machine, the owner will soon break it in more manageable chunks and sell it for scrap. As he has donated the other machines to Tuckahoe, he is willing to donate this one to any other non-profit institution that is willing to take care of it.

Unfortunately, when I was there, the space was scrammed with other machines and there was not enough room for taking more decent pictures and I'm still waiting for better pictures from the son of the owner.

A distinctive peculiarity of this lathe is the flat turret: Mr Hartness invented this style of turret with the height lower than the spindle axis, so that long stock could be accommodated. He patented and, at the beginning of the 1900, he was receiving $100 in royalties for each of these lathes sold.

Another interesting feature is that the whole headstock can translate side-wise, while keeping all the mechanical connections with all the feeds.

Lastly, another distinctive feature of this lathe is the system of stops for the turret: rectangular bars between the ways, clamped at the tailstock side:

Here you can find the manual for this lathe

Even if you are unable to rescue it yourself, please, forward the link to this thread to anybody who could be interested. We would really hate to see it chopped to pieces.

Of course, if you're interested, send me a private message.

Thanks!

Paolo