How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Identify antique metal punch

- Thread starter Langerboo

- Start date

- Replies 11

- Views 5,610

I think Ryerson was the sales company, not the manufacturer. I think the name is obscured by the electrical flex is the manufacturer. A brief search found a Rock River Machine Company listed under press manufacturers, possibly selling under the Badger brand.

I think it was a dual purpose machine of some type. I'm guessing it could be used as a stamping press with a large throat, probably with positive location of the punch so a die set wasn't needed. In its current form with the tie rods installed it can be used as a standard stamping press. The eccentric rather than a connecting rod is a unique feature.

The frame looks quite stout compared to the slender tie rods.

I think it was a dual purpose machine of some type. I'm guessing it could be used as a stamping press with a large throat, probably with positive location of the punch so a die set wasn't needed. In its current form with the tie rods installed it can be used as a standard stamping press. The eccentric rather than a connecting rod is a unique feature.

The frame looks quite stout compared to the slender tie rods.

I think you're right regarding the manufacturer etc... I got word back from a colleague in the shop who said that the main body was made by Badger State Machine Company and sold under the Rock River machine Company name. The motor in rear is from the Crocker, Wheeler Electric Company which should date it to 1949 or older because Crocker was sold to a different company in '49.

He's guessing it was probably built between the early 1930s and the early 1950s. Seem accurate?

He's guessing it was probably built between the early 1930s and the early 1950s. Seem accurate?

SouthBendModel34

Diamond

- Joined

- Feb 4, 2004

- Location

- Metuchen, NJ, USA

Inventory Tag?

This last one (Post #4) appears to be an owner's inventory tag.

Note that the "NC" is in raised relief, while the rest of that line (? PS163 ?) is hand-stamped with loose stamps. The previous owner had brass tags made up with everything up to the "NC", and then they stamped the individual machine's identifiers on them with hand stamps.

It's a tag used to identify the machine for annual inventory, etc. Having a standard tag like this saves labor at every inventory; there's no searching all over every machine to find its maker and serial number. The inventory can be done by any auditor, without knowledge of where to search for the builder's plate.

The War Department and later Dept. of Defense had tags like this for machines which were owned by Uncle Sam and used in gov't arsenals and shipyards or loaned out to defense contractors. However, I don't think this is a government tag - my SWAG is that it is an owner's tag.

Such tags also appear on machines which are "mortgaged" through an equipment trust.

A gentle application of Brasso to that tag might reveal the identity of a previous owner.

John Ruth

This last one (Post #4) appears to be an owner's inventory tag.

Note that the "NC" is in raised relief, while the rest of that line (? PS163 ?) is hand-stamped with loose stamps. The previous owner had brass tags made up with everything up to the "NC", and then they stamped the individual machine's identifiers on them with hand stamps.

It's a tag used to identify the machine for annual inventory, etc. Having a standard tag like this saves labor at every inventory; there's no searching all over every machine to find its maker and serial number. The inventory can be done by any auditor, without knowledge of where to search for the builder's plate.

The War Department and later Dept. of Defense had tags like this for machines which were owned by Uncle Sam and used in gov't arsenals and shipyards or loaned out to defense contractors. However, I don't think this is a government tag - my SWAG is that it is an owner's tag.

Such tags also appear on machines which are "mortgaged" through an equipment trust.

A gentle application of Brasso to that tag might reveal the identity of a previous owner.

John Ruth

Last edited:

Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

Joseph Ryerson, of Chicago, was a supplier of machine tools and fabrication machinery. I've seen the Ryerson name on an old engine lathe and drill press in the machine shop of a Great Lakes ore boat years ago. I have also seen the Ryerson name on mechanical "ironworkers" (a multi purpose machine which can punch, notch, and do other fabrication operations on structural steel). I believe that same Ryerson also was a supplier of steel in the form of plate, structural shapes (angle, channel, etc) and tube and pipe. The name Ryerson survives to this day as a supplier of mainly steel- structural, plate, and pipe and tube.

The press or punch in this thread was likely supplied by Ryerson was likely sold originally as a punch to be used for punching multiple holes for riveted connections on structural steel. In a steel fabrication plant in riveted days, many of the same riveted connection would need to be punched on structural members. Something like connector plates, clip angles, or webs of "I" or "widflange" sections would need to have holes punched for riveted connections with the same hole layout. This machine, equipped with a die-set having multiple punches, would be used.

Look at a riveted structure like a truss bridge and you will see a large number of connections with the same layout of rivets. Rather than keep men busy with rules, squares, dividers and punches laying out each connection, a multiple punch setup on this type press would be used.

Ryerson also made single punches for punching single holes in structural steel. I do not think Ryerson ever made any machine tools on their own. They started in Chicago as a supplier of steel and other metals along with machinists and boilermakers supplies. For some time in my career, I kept a Ryerson pocket guide to various steel products at hand. Ryerson could supply floor grating, diamond plate, as well as aluminum structural shapes and plates and steel in all manner of structural shapes and plate. Ryerson had branches or distribution centers around the USA and was no small firm by the middle of the 20th Century. At some point, Ryerson was absorbed or merged into, Inland Steel and was known as "Inryco". What their present status is, is something I do not know, but I still have one of their pocket guides to steel and aluminum structural shapes, plate, gratings, etc.

The press or punch in this thread was likely supplied by Ryerson was likely sold originally as a punch to be used for punching multiple holes for riveted connections on structural steel. In a steel fabrication plant in riveted days, many of the same riveted connection would need to be punched on structural members. Something like connector plates, clip angles, or webs of "I" or "widflange" sections would need to have holes punched for riveted connections with the same hole layout. This machine, equipped with a die-set having multiple punches, would be used.

Look at a riveted structure like a truss bridge and you will see a large number of connections with the same layout of rivets. Rather than keep men busy with rules, squares, dividers and punches laying out each connection, a multiple punch setup on this type press would be used.

Ryerson also made single punches for punching single holes in structural steel. I do not think Ryerson ever made any machine tools on their own. They started in Chicago as a supplier of steel and other metals along with machinists and boilermakers supplies. For some time in my career, I kept a Ryerson pocket guide to various steel products at hand. Ryerson could supply floor grating, diamond plate, as well as aluminum structural shapes and plates and steel in all manner of structural shapes and plate. Ryerson had branches or distribution centers around the USA and was no small firm by the middle of the 20th Century. At some point, Ryerson was absorbed or merged into, Inland Steel and was known as "Inryco". What their present status is, is something I do not know, but I still have one of their pocket guides to steel and aluminum structural shapes, plate, gratings, etc.

moonlight machine

Diamond

- Joined

- Nov 19, 2007

- Location

- marysville ohio

Back when I lived in Minnesota I used to buy metal from Ryerson, the truck driver on my route was called "tiny". I'll never forget a piece of 3/4" steel 20" x 72", blanchard ground both sides. Tiny stopped on the road to unload as usual, way too much hassle to back the semi off the narrow gravel road. he carried it in 1 hand under his arm from the road 150' or so back to the shop. Needless to say Tiny was Huge! I used to work on his Harley. It looked like a moped with him sitting on it.

Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

By way of curiosity, I figured the weight of that chunk of Blanchard ground plate. 3/4" plate is 30 lb/sq ft, and the area of that plate was 9.996 sq ft. That was 300 lbs of plate Tiny carried down the road to your shop.

I think we've all worked with men like Tiny at some point in our lives. They take their strength for granted and are most usually gentle souls who are among the last people to look for trouble.

I remember the Ryerson steel trucks coming to deliver steel to my neighbors' shop in the Upper Peninsula. The Ryerson drivers were like club members or neighbors, even though they came out of a Ryerson depot in Green Bay, a good 150 or so miles away. They'd deliver the steel, stop for a cup of coffee, visit and catch up on people and events, and then climb aboard their steel truck and push on. The first job I did on my license as a Professional Engineer was in 1977 for my neighbors. It was my gift to them, and it was the design of a 40' x 80' addition to their shop with a bridge crane runway in it. In short order, they were selling more retail steel than I think they ever imagined. With a track torch and the bridge crane, they were in high cotton. Ryerson went from sending a straight flatbed truck out their way to often having to send a semi. 40 years later, I visited my neighbors in the UP at their shop- they are semi retired and I am "retired" as well. Their sons run the shop, but as we sat in the office going over old times and catching up and their getting to know my wife (of 34 years, no less), the Ryerson truck arrived. Like old times, the Ryerson driver climbed out of his cab and was soon sitting in the office with a cup of coffee. I went back into the addition I'd design, and with my old neighbor, we got a plate grab and slings and unloaded the steel with the bridge crane. We both found it to be a nostalgic and sweet moment as we recollected and wondered where 40 years had gone, and set the steel off in the shop.

I think we've all worked with men like Tiny at some point in our lives. They take their strength for granted and are most usually gentle souls who are among the last people to look for trouble.

I remember the Ryerson steel trucks coming to deliver steel to my neighbors' shop in the Upper Peninsula. The Ryerson drivers were like club members or neighbors, even though they came out of a Ryerson depot in Green Bay, a good 150 or so miles away. They'd deliver the steel, stop for a cup of coffee, visit and catch up on people and events, and then climb aboard their steel truck and push on. The first job I did on my license as a Professional Engineer was in 1977 for my neighbors. It was my gift to them, and it was the design of a 40' x 80' addition to their shop with a bridge crane runway in it. In short order, they were selling more retail steel than I think they ever imagined. With a track torch and the bridge crane, they were in high cotton. Ryerson went from sending a straight flatbed truck out their way to often having to send a semi. 40 years later, I visited my neighbors in the UP at their shop- they are semi retired and I am "retired" as well. Their sons run the shop, but as we sat in the office going over old times and catching up and their getting to know my wife (of 34 years, no less), the Ryerson truck arrived. Like old times, the Ryerson driver climbed out of his cab and was soon sitting in the office with a cup of coffee. I went back into the addition I'd design, and with my old neighbor, we got a plate grab and slings and unloaded the steel with the bridge crane. We both found it to be a nostalgic and sweet moment as we recollected and wondered where 40 years had gone, and set the steel off in the shop.

moonlight machine

Diamond

- Joined

- Nov 19, 2007

- Location

- marysville ohio

300 lbs sounds about right. He leaned it against the wall by the door. Later I needed the engine hoist to move it!

Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

Rule of thumb for figuring the weight of steel plate: 1/8" thick steel plate weighs 5 lbs (approximately). To get the weight of a piece of steel plate, measure the thickness in 1/8ths of an inch, multiply by 5 lbs and you have the weight per square foot. Handy to remember:

1/2" plate is 20 lbs/sq ft and 1" plate is 40 lbs per sq/ft. Steel has a specific weight of 480 lbs per cubic foot, or 4.4 ounces per cubic inch. Water weighs 62.4 lbs per cubic foot, and concrete weighs 150 lbs per cubic foot or 4050 lbs/cubic yard. These are handy numbers to have in your memory bank as it helps to estimate weights or loads.

Dinosaurs such as myself carry this kind of information around in our heads from the days before pocket-sized devices storing all manner of information were even a glimmer on the horizon.

1/2" plate is 20 lbs/sq ft and 1" plate is 40 lbs per sq/ft. Steel has a specific weight of 480 lbs per cubic foot, or 4.4 ounces per cubic inch. Water weighs 62.4 lbs per cubic foot, and concrete weighs 150 lbs per cubic foot or 4050 lbs/cubic yard. These are handy numbers to have in your memory bank as it helps to estimate weights or loads.

Dinosaurs such as myself carry this kind of information around in our heads from the days before pocket-sized devices storing all manner of information were even a glimmer on the horizon.

Hey Thanks all for the responses!

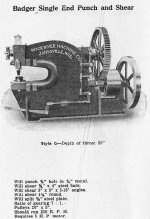

Making further progress with the help of our machine shop, I think I found it in this Rock River Machine Co. Catalogue: Badger State Machine Co. - Publication Reprints - Rock River Machine Co. | VintageMachinery.org

Wondering if it might be this Badger Single End Punch and Shear with the gear guards and motor drive added. Perhaps either the style E or style G? don't have the throat depth yet which would help. Any thoughts?

Example with attached motor drive:

Making further progress with the help of our machine shop, I think I found it in this Rock River Machine Co. Catalogue: Badger State Machine Co. - Publication Reprints - Rock River Machine Co. | VintageMachinery.org

Wondering if it might be this Badger Single End Punch and Shear with the gear guards and motor drive added. Perhaps either the style E or style G? don't have the throat depth yet which would help. Any thoughts?

Example with attached motor drive:

Similar threads

- Replies

- 19

- Views

- 860

- Replies

- 2

- Views

- 251

- Replies

- 10

- Views

- 756

- Replies

- 26

- Views

- 2K

- Replies

- 115

- Views

- 6K