rivett608

Diamond

- Joined

- Oct 25, 2002

- Location

- Kansas City, Mo.

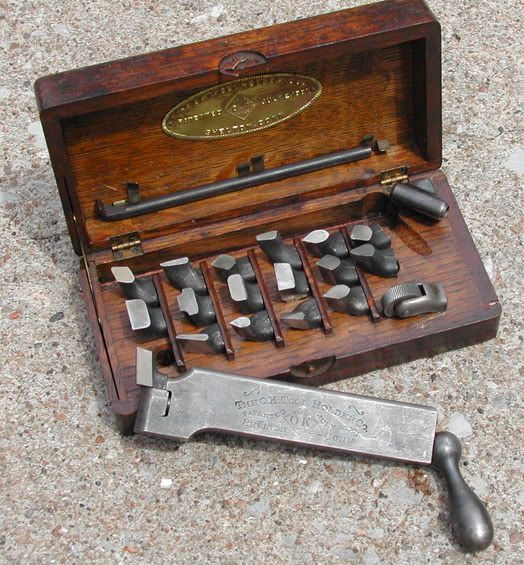

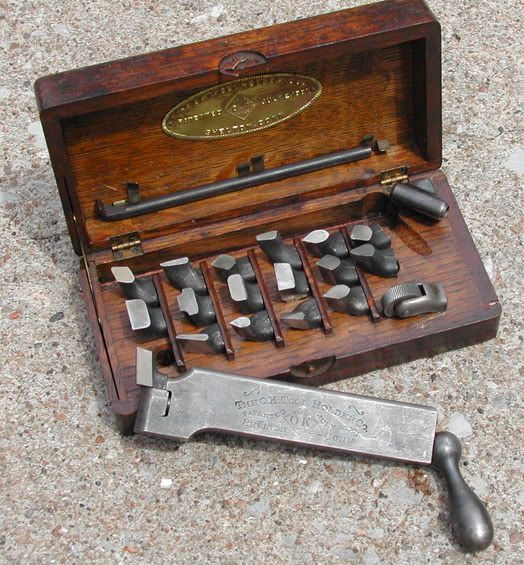

The idea of a toolholder with replaceable inserts has been around a while.... this one was patented on July 2 1901 by THE O.K. TOOL HOLDER CO. of Sheldon Conn... this is their complete set, size "B", with internal threading and knurling tools..... all inserts are made of "Jessops Steel" according to the catalog, what's that? Always nice to see tools that the makers were proud of... note the brass plate and nice stamping on the side of the holder.

Thanks for sharing.

Thanks for sharing.