Peter S

Diamond

- Joined

- May 6, 2002

- Location

- Auckland, New Zealand

In the recent "Lidgerwood" thread, Jim Christie used his great research skills to find an interesting article in the December 1909 Railway Master Mechanic Journal. It featured the Lidgerwood high speed cableways used to build the Gatun Locks on the Panama Canal.

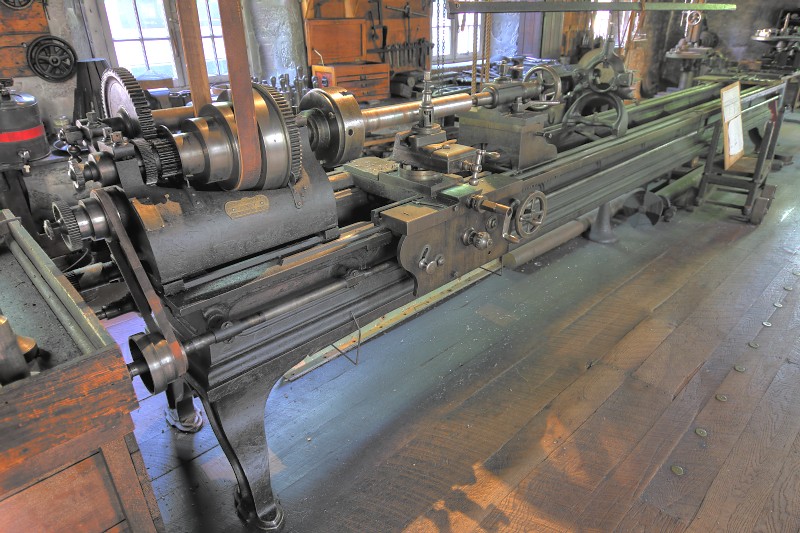

I looked at a few other pages of the same magazine and came across this rather attractive lathe from 1854, still in use in 1909. Does anyone recognise it?

BTW, the article was about electric drives for machine tools.

Railway master mechanic [microform]

I looked at a few other pages of the same magazine and came across this rather attractive lathe from 1854, still in use in 1909. Does anyone recognise it?

BTW, the article was about electric drives for machine tools.

Railway master mechanic [microform]