rvannatta

Hot Rolled

- Joined

- May 27, 2006

- Location

- Rainier, Oregon

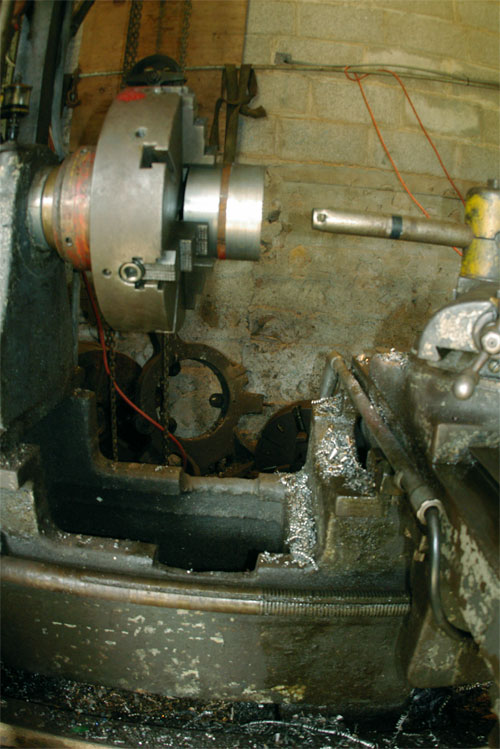

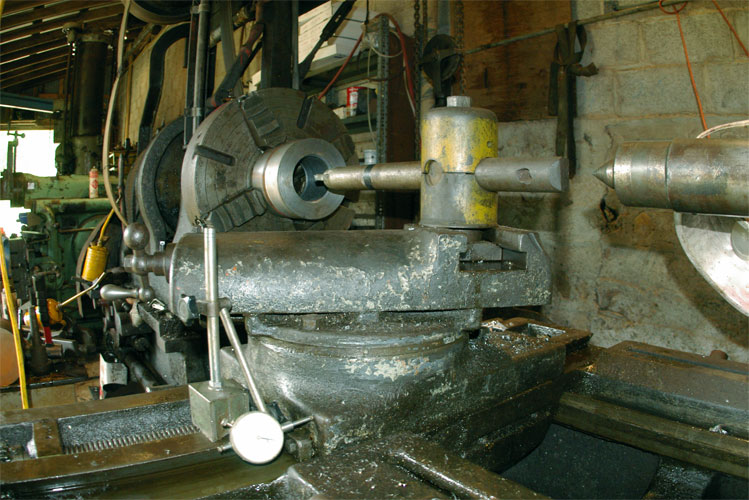

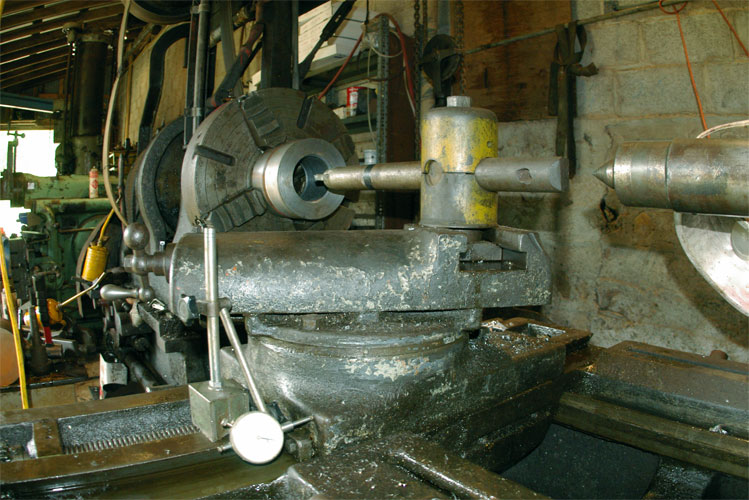

What follows is a photo of my London Machine tool lathe instrumented and configured for threading.

What interests me in the position of the compound. All the manuals I've seen on cutting threads with a lathe show the compound 180 degrees from the position shown here, however with the geometry of this lathe that is just impossible. The cross slide won't go over far enough to allow small diameter threading if the compound is rotated with the handle to the back.

Besides that you couldn't reach the handle anyway.

the lathe will swing modestly over 4 feet in the gap, and it appears that if you were doing large diameter thread cutting (say over a couple feet) you could rotate the compound into the classic backwards position (for internal threads)

Any thoughts as to whether this is 'normal' for old lathes or unique to this model

The black tape on the boring bar servies as a high tech depth gauge. There are some surviving degree markers on the compound swing,on the front side, but a couple of punch marks on the back side mark the spot for setting the compound.

What interests me in the position of the compound. All the manuals I've seen on cutting threads with a lathe show the compound 180 degrees from the position shown here, however with the geometry of this lathe that is just impossible. The cross slide won't go over far enough to allow small diameter threading if the compound is rotated with the handle to the back.

Besides that you couldn't reach the handle anyway.

the lathe will swing modestly over 4 feet in the gap, and it appears that if you were doing large diameter thread cutting (say over a couple feet) you could rotate the compound into the classic backwards position (for internal threads)

Any thoughts as to whether this is 'normal' for old lathes or unique to this model

The black tape on the boring bar servies as a high tech depth gauge. There are some surviving degree markers on the compound swing,on the front side, but a couple of punch marks on the back side mark the spot for setting the compound.