How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hendey teardown

- Thread starter Sheraton2

- Start date

- Replies 12

- Views 2,146

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

First an apology - near end of posts here

Hi, New member and another Hendey Lathe (in Australia)

I took your description of "Taper Bearings" to mean Hendey's long used plain bearings.

Photos in this new thread show that not to be the case at all - those are Timken taper roller bearings

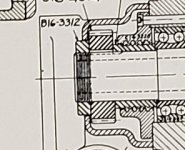

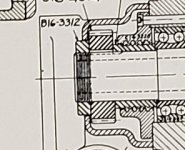

Here is the type of view that may help - maybe hendeyman has a higher resolution version

The tail end ring nut B16-3312 can be removed and the front ring nut C16-3833 certainly would have to be incrementally backed off as spindle was nudged thru bull gear and front pair of bearings. Maybe there are ring nuts I missed.

It will be smart to NOT try to turn ring nuts until you know for a fact there are no set screws in them preventing their turning

ON EDIT - looks like a third ring nut left end of bull gear - B16-3243

Hi, New member and another Hendey Lathe (in Australia)

I took your description of "Taper Bearings" to mean Hendey's long used plain bearings.

Photos in this new thread show that not to be the case at all - those are Timken taper roller bearings

Here is the type of view that may help - maybe hendeyman has a higher resolution version

The tail end ring nut B16-3312 can be removed and the front ring nut C16-3833 certainly would have to be incrementally backed off as spindle was nudged thru bull gear and front pair of bearings. Maybe there are ring nuts I missed.

It will be smart to NOT try to turn ring nuts until you know for a fact there are no set screws in them preventing their turning

ON EDIT - looks like a third ring nut left end of bull gear - B16-3243

Last edited:

HendeySwede

Aluminum

- Joined

- Mar 31, 2018

Hi Sheraton2,

Removal of spindle is well described in OP manual - can be obtained from Hendeyman or Tonylathes UK. Contains a lot of useful information. And yes, there are set screws in all 3 collars. You might find something useful from a thread I posted abt a year ago:

"Hendey geared head lathe - noisy and leaking"

Good luck and pls let us know how things develop.

Lars

Removal of spindle is well described in OP manual - can be obtained from Hendeyman or Tonylathes UK. Contains a lot of useful information. And yes, there are set screws in all 3 collars. You might find something useful from a thread I posted abt a year ago:

"Hendey geared head lathe - noisy and leaking"

Good luck and pls let us know how things develop.

Lars

OK thanks for the diagrams John. I will carefully check for any set screws . I will make a puller . There seems to be a key that locks the rearmost Timken bearing in place.OK Lars I will look for your previous blog ... Thanks Hendey geared head lathe - noisy and leaking - remedies? This is a 12 speed I have, think Lars has a 18 speed but the disassembly methods do apply for both types I think.

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

These are direct from manual - and says they are for 18 speed. Funny thing over a few pages says a similar view - except old plain bearings - is for both 12 and 18 speed

So - use if looks applicable for what you are looking at

These would no doubt be higher resolution if emailed - if you want to private message me that address with something useful in the subject line so I will have a clue as to what is wanted

So - use if looks applicable for what you are looking at

These would no doubt be higher resolution if emailed - if you want to private message me that address with something useful in the subject line so I will have a clue as to what is wanted

OK John the diagrams are very helpful

I have made a little progress. I removed the set screw and unscrewed the first collar . On this model, there seems to be a sheet metal cover over the forward end where the two tapered bearings are ? I have to first remove that sheet metal cover to get to the next set screw and collar and then the locking key in the tapered bearing

I have made a little progress. I removed the set screw and unscrewed the first collar . On this model, there seems to be a sheet metal cover over the forward end where the two tapered bearings are ? I have to first remove that sheet metal cover to get to the next set screw and collar and then the locking key in the tapered bearing

Attachments

cover

Can't figure out how to remove this sheet metal cover, the cover seems to go right round the spindle. Can't see anything like it on the diagrams or instructions mentioned in the OP manual . The manuals seem to be for later variants of this lathe, I need a earlier manual I think ?

PS got the cover off OK. Now I have to move the bull gear back a bit and unscrew the last collar .

Can't figure out how to remove this sheet metal cover, the cover seems to go right round the spindle. Can't see anything like it on the diagrams or instructions mentioned in the OP manual . The manuals seem to be for later variants of this lathe, I need a earlier manual I think ?

PS got the cover off OK. Now I have to move the bull gear back a bit and unscrew the last collar .

Attachments

Last edited:

HendeySwede

Aluminum

- Joined

- Mar 31, 2018

Sheraton2,

Removing spindle - seems like you are on the right track now. Just a kind reminder: when pulling the spindle, take your time and note position of all gears, collars and ev. shims as they come off.

Wonder why your spindle bearings are worn - could they have been adjusted too tight? Were there signs of rough handling - hammer and mandrel instead of hooked spanners? Or was it simply due to metal chips in the oil? I put a magnet in the drain plug on my own late hoping it will collect at least some of the miniflakes.

Pls keep posting picures.

Lars

Removing spindle - seems like you are on the right track now. Just a kind reminder: when pulling the spindle, take your time and note position of all gears, collars and ev. shims as they come off.

Wonder why your spindle bearings are worn - could they have been adjusted too tight? Were there signs of rough handling - hammer and mandrel instead of hooked spanners? Or was it simply due to metal chips in the oil? I put a magnet in the drain plug on my own late hoping it will collect at least some of the miniflakes.

Pls keep posting picures.

Lars

Sheraton2,

Removing spindle - seems like you are on the right track now. Just a kind reminder: when pulling the spindle, take your time and note position of all gears, collars and ev. shims as they come off.

Wonder why your spindle bearings are worn - could they have been adjusted too tight? Were there signs of rough handling - hammer and mandrel instead of hooked spanners? Or was it simply due to metal chips in the oil? I put a magnet in the drain plug on my own late hoping it will collect at least some of the miniflakes.

Pls keep posting picures.

Lars

Ah thanks Lars. Yes I am not rushing this job , it's so easy to break something .

I have the last set screw undone and the collar that sits right on the forward bearing ( providing the preload ) is unscrewed , but I need to unscrew it some more. The large gear directly behind the collar needs to be slid rearwards, but that gear is in mesh with a smaller pinion gear on the back gear and being helical gears they won't slide apart easily. I might have to undo the back gear pinion bearing in order to move give the back gear some side ways free play. Lars can you remember how you did this ?

I hope this blog will help out other Hendey owners . Reason for the disassembly is a clean out of the metal fragments I found in the oil and a check of the bearings, the bearings do sound rather scratchy and rumbling

Attachments

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

I think lateral movement in a helical pair just requires a bit of "unscrewing"

If that is possible

If that is possible

Paolo_MD

Stainless

- Joined

- Apr 6, 2013

- Location

- Damascus, MD

My understanding is that the backgears remain in mesh, while the spindle is sliding out. I think that the relative movement back and forth of the bullgear during disassembly is at most 1/4"

Recently I have disassembled the headstock of Tuckahoe's 8 speed gearhead and everything seemed straightforward.

To pull the spindle out I have used all-thread, a plug for the back of the spindle and a 3 ft piece of PVC pipe (I believe 6" in diameter to clear the front of the spindle).

Paolo

Recently I have disassembled the headstock of Tuckahoe's 8 speed gearhead and everything seemed straightforward.

To pull the spindle out I have used all-thread, a plug for the back of the spindle and a 3 ft piece of PVC pipe (I believe 6" in diameter to clear the front of the spindle).

Paolo

HendeySwede

Aluminum

- Joined

- Mar 31, 2018

Sheraton2,

I don't remember having any problems backing off retaining collars - the Hendey manuals do not make any distinction between 12 or 18 speeds. You will not be able to back off the collars completely, there is not space enough. Instead you undo them bit by bit as you pull out the spindle. You have to move the sliding clutch as far as possible to the left with the dogs engaged. You should then be able to slide big gear to the left, again creating as much space as possible by engaging the dogs. The helical gear is not the problem. The big gear should slide freely when collar loosened. If you think the helical gear is the problem, then try to spin the intermediate shaft or find a neutral with gear shift levers (between the positioning slots.)

I think you will figure it out.

Lars

I don't remember having any problems backing off retaining collars - the Hendey manuals do not make any distinction between 12 or 18 speeds. You will not be able to back off the collars completely, there is not space enough. Instead you undo them bit by bit as you pull out the spindle. You have to move the sliding clutch as far as possible to the left with the dogs engaged. You should then be able to slide big gear to the left, again creating as much space as possible by engaging the dogs. The helical gear is not the problem. The big gear should slide freely when collar loosened. If you think the helical gear is the problem, then try to spin the intermediate shaft or find a neutral with gear shift levers (between the positioning slots.)

I think you will figure it out.

Lars

Sheraton2,

I don't remember having any problems backing off retaining collars - the Hendey manuals do not make any distinction between 12 or 18 speeds. You will not be able to back off the collars completely, there is not space enough. Instead you undo them bit by bit as you pull out the spindle. You have to move the sliding clutch as far as possible to the left with the dogs engaged. You should then be able to slide big gear to the left, again creating as much space as possible by engaging the dogs. The helical gear is not the problem. The big gear should slide freely when collar loosened. If you think the helical gear is the problem, then try to spin the intermediate shaft or find a neutral with gear shift levers (between the positioning slots.)

I think you will figure it out.

Lars

Thanks Lars

Its OK, I managed to rotate the front collar some more and the spindle is now coming out slowly ! Previously I was being a bit too gentle, but I decided to just tap the collar around some more with a screwdriver fitted in the slots on the collar circumference , it was a little tight to begin with but its coming off Ok now.

Yes I now realize the back gears meshing isn't a problem.

Thanks Paulo . Yes I will find a length of allthread if I need to go to that method and apply more force but the spindle appears to be coming out OK now.

Attachments

Similar threads

- Replies

- 8

- Views

- 735

- Replies

- 2

- Views

- 462

- Replies

- 12

- Views

- 726