Jim Christie

Titanium

- Joined

- Mar 14, 2007

- Location

- L'Orignal, Ontario Canada

I’m not sure if there has been a link posted to this catalogue some where before a search gave me too many possibilities to try so sorry if it is a repeat.

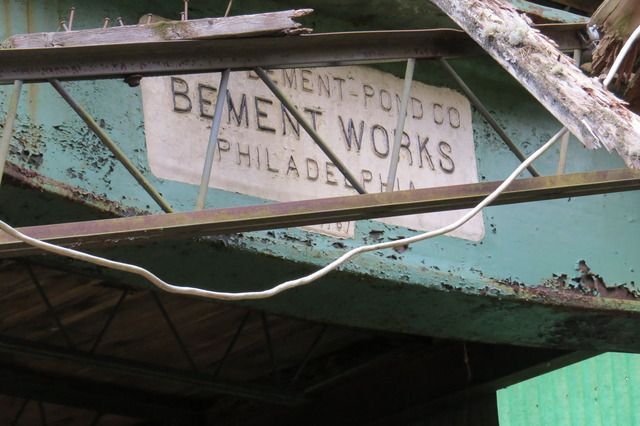

Niles-Bement-Pond Company Machine Tools Catalogue 1903

Machine tools / Niles-Bement-Pond Company. - Full View | HathiTrust Digital Library | HathiTrust Digital Library

They appeared to be dealers for Pratt and Whitney machines as well as the larger machines that the built them selves.

Here are a few highlights .

The Section on Lathes Starts here with the Pratt and Whitney 7 x 32” bench Lathe

Machine tools / Niles-Bement-Pond Company. - Full View | HathiTrust Digital Library | HathiTrust Digital Library

Scroll down for other Pratt and Whitney Lathes

Heavy Engine Lathes by Pond Machine Works starts here

Machine tools / Niles-Bement-Pond Company. - Full View | HathiTrust Digital Library | HathiTrust Digital Library

Planers start here

Machine tools / Niles-Bement-Pond Company. - Full View | HathiTrust Digital Library | HathiTrust Digital Library

P & W Hand Milling Machines Start Here

Machine tools / Niles-Bement-Pond Company. - Full View | HathiTrust Digital Library | HathiTrust Digital Library

There are some 700 pages + index so I have not looked at it all.

Regards,

Jim

Niles-Bement-Pond Company Machine Tools Catalogue 1903

Machine tools / Niles-Bement-Pond Company. - Full View | HathiTrust Digital Library | HathiTrust Digital Library

They appeared to be dealers for Pratt and Whitney machines as well as the larger machines that the built them selves.

Here are a few highlights .

The Section on Lathes Starts here with the Pratt and Whitney 7 x 32” bench Lathe

Machine tools / Niles-Bement-Pond Company. - Full View | HathiTrust Digital Library | HathiTrust Digital Library

Scroll down for other Pratt and Whitney Lathes

Heavy Engine Lathes by Pond Machine Works starts here

Machine tools / Niles-Bement-Pond Company. - Full View | HathiTrust Digital Library | HathiTrust Digital Library

Planers start here

Machine tools / Niles-Bement-Pond Company. - Full View | HathiTrust Digital Library | HathiTrust Digital Library

P & W Hand Milling Machines Start Here

Machine tools / Niles-Bement-Pond Company. - Full View | HathiTrust Digital Library | HathiTrust Digital Library

There are some 700 pages + index so I have not looked at it all.

Regards,

Jim