Asquith

Diamond

- Joined

- Mar 3, 2005

- Location

- Somerset, UK

This 1850s shaper by William Collier is on display at the excellent Museum of Bath at Work. It’s in a lineshaft workshop which can be viewed from above, but close access to the machines is only by arrangement. I’m very grateful to the museum director, Stuart Burroughs, for allowing this.

The machines, and hundreds of other items on display were brought from the works of Messrs Bowler in Bath. Bowler’s were plumbers, brass founders, general engineers, bell-hangers, and makers of …… carbonated drinks!

For more information about William Collier & Co, see:-

http://www.practicalmachinist.com/v...-mill-engines-146469/index37.html#post1661288

For more information about an old milling machine in this collection, and links to other threads about the museum, see:-

http://www.practicalmachinist.com/vb/antique-machinery-history/1880s-milling-machine-233153/

Now, down to detail:

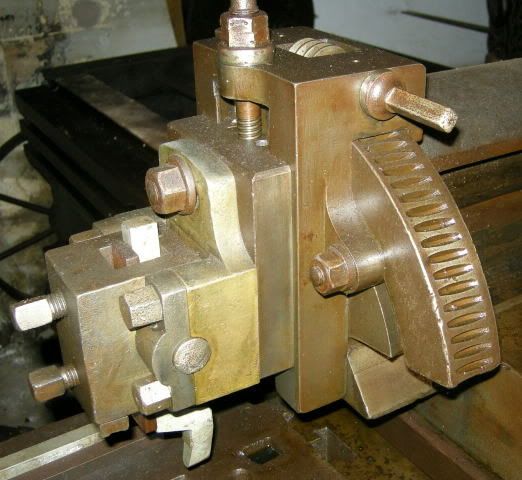

It’s a travelling head shaper. As the name implies, the whole head travels along the bed, and, shapes. The big flywheel/handwheel is on the power feed shaft. The shaft has a full length keyway which drives a sliding pinion. This pinion drives the big gearwheel in the photo above. Behind the gearwheel is the fast return link that strokes the shaper arm. On the camera side of the gear can be seen the slotted disc which operates the rod for the automatic feed.

The smaller handwheel engages with the feed mechanism, ultimately reaching a gear wheel mounted on the stationary leadscrew.

We’ll return to the mechanisms later

I think the swivelling head is quite nicely designed and made. Not sure about the brass block. I suspect this was a replacement, possibly made by Bowler’s since they had a foundry keen to make brass castings.

Note the worm in the foreground. This would have engaged with a wheel on a spindle protruding from the bed, allowing cylindrical surfaces to be shaped. The worm had an incremental power feed.