JBoogie

Cast Iron

- Joined

- May 23, 2011

- Location

- Toledo, oHIo

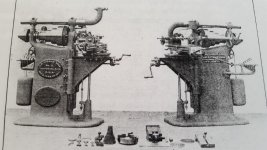

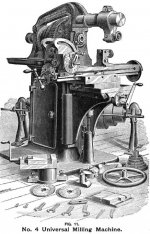

Just picked up this old mill. It's very complete. Still has the plugs for the spindle oil holes, oil drip can, differential indexing head and some other stuff. Someone did a decent overhead drive conversion along the way. Everything feels pretty tight. The Cope book says this style came out in 1892. Looks like it came from the factory with green paint.