Peter S

Diamond

- Joined

- May 6, 2002

- Location

- Auckland, New Zealand

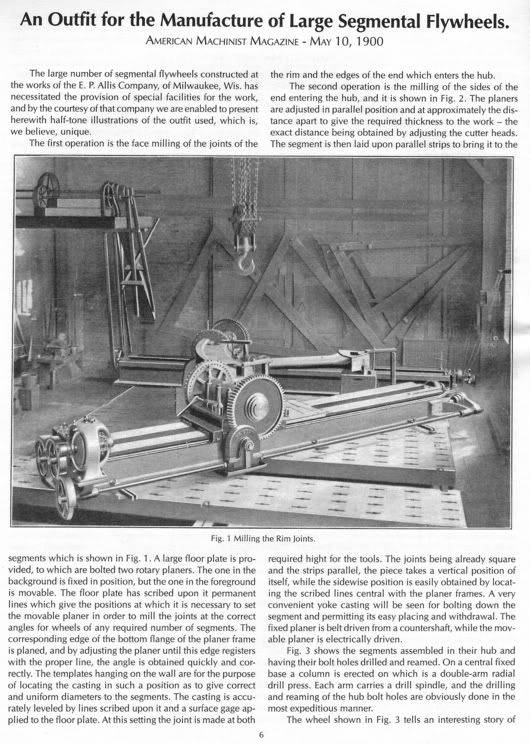

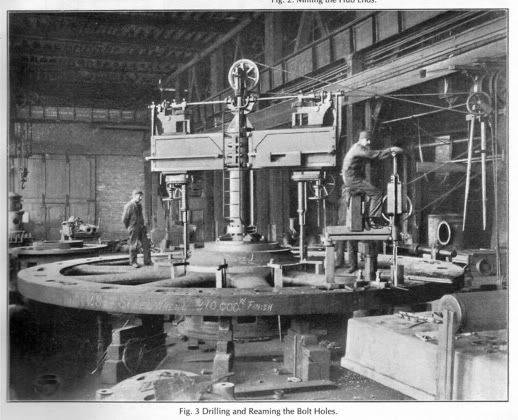

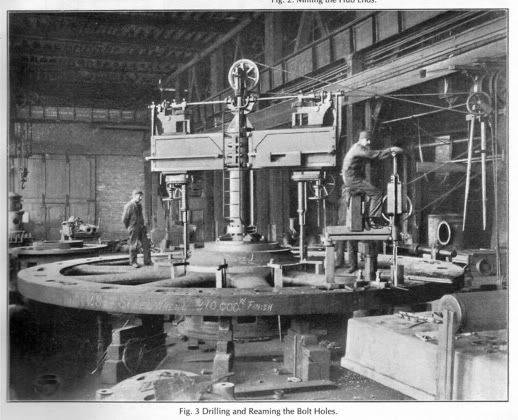

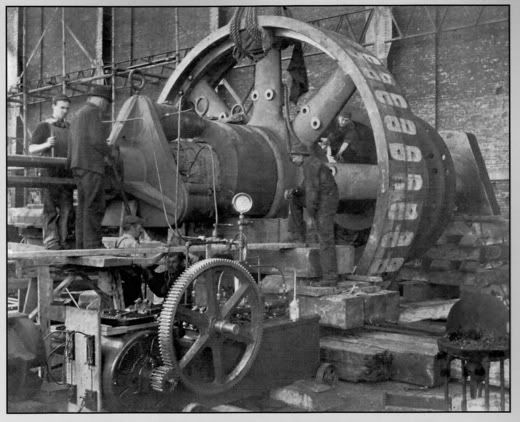

The recent thread about flywheel explosions set me looking at some articles, here is a photo showing the construction of a massive flywheel at the E.P. Allis Company. This photo is part of an article about flywheel manufacture that was published in American Machinist Magazine in 1900 and reprinted in a fairly recent Lindsay book "American Machinist Memories: Engines 1900-02"

The flywheel is for one of the 11 engines being built for the new power house of the Metropolitan Street Railway Company in New York.

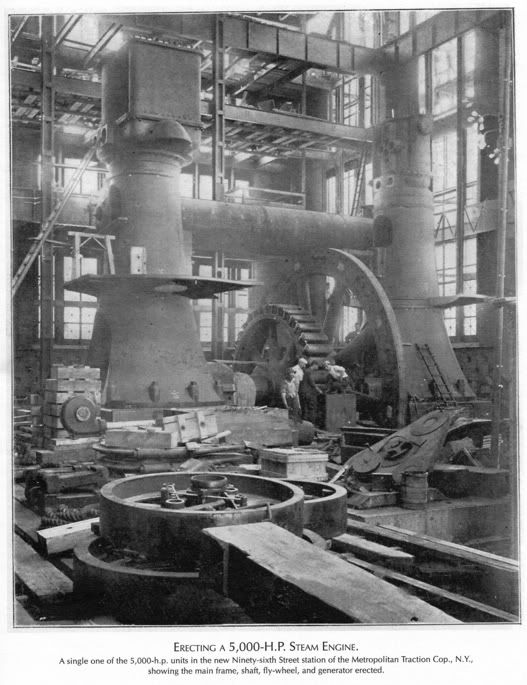

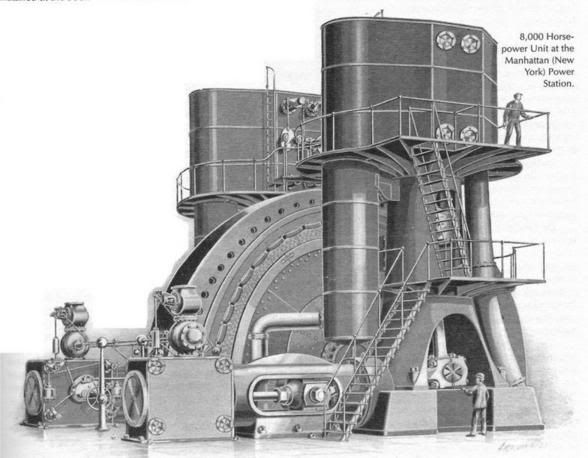

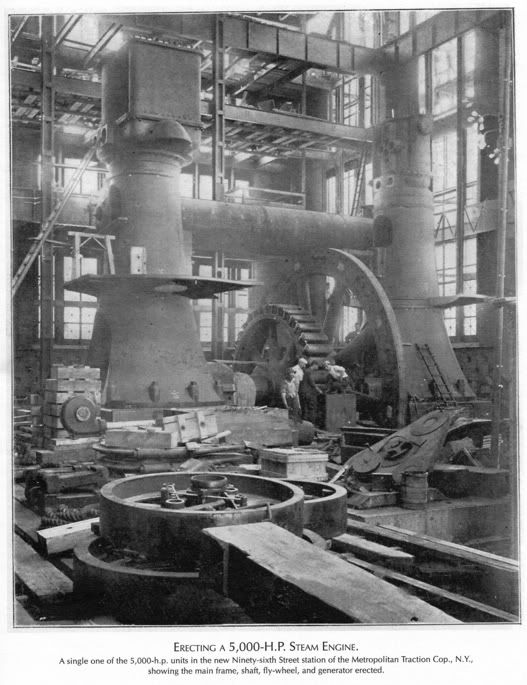

There are also photos of engines being installed at the 96th Street power house of the Metropolitan Traction Co. of NY, I am not sure if they are the same company and engines, though they look similar. They are 5000hp vertical cross-compounds generating electricity.

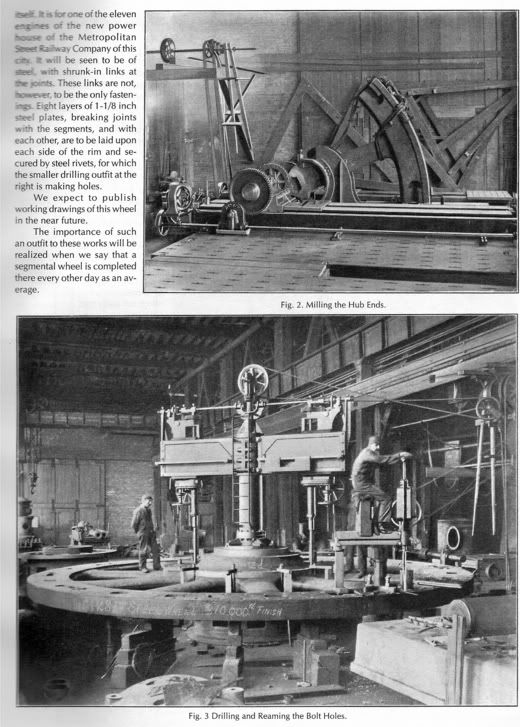

Anyway, here is one of the flywheels. Because of the tremendous power of the engine, and the particular danger that a generating engine has of overspeeding, it is made of cast steel, except for having a cast iron hub. It is 28' dia, weighs 310,000 lbs and is made in segments.

The man on the rim is drilling and reaming the holes which will be used to rivet on steel plates, 1-1/8" thick either side of the rim. These plates overlap the segment joints.

The article says that the works, on average, complete one segmental wheel every other day. An accompanying drawing shows that the spokes are hollow, but with a wall thickness of 3" in a radial cross-section.

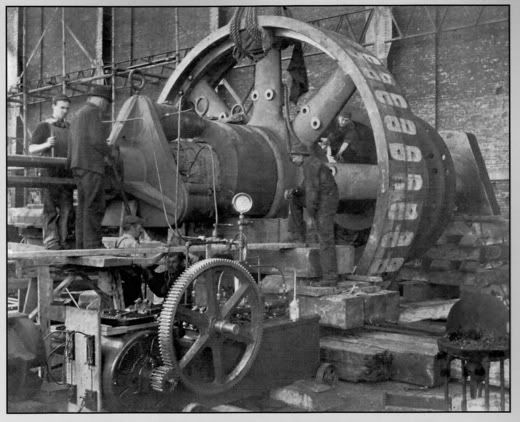

This next photo just looked interesting - not exactly a flywheel, but the 'spider' for the generator, it fits alongside the flywheel (not yet fitted). They are using electric-driven hydraulic presses to fit the spider onto the shaft. (5000hp engine)

And here is a photo of one of the engines in a more complete state.

The flywheel is for one of the 11 engines being built for the new power house of the Metropolitan Street Railway Company in New York.

There are also photos of engines being installed at the 96th Street power house of the Metropolitan Traction Co. of NY, I am not sure if they are the same company and engines, though they look similar. They are 5000hp vertical cross-compounds generating electricity.

Anyway, here is one of the flywheels. Because of the tremendous power of the engine, and the particular danger that a generating engine has of overspeeding, it is made of cast steel, except for having a cast iron hub. It is 28' dia, weighs 310,000 lbs and is made in segments.

The man on the rim is drilling and reaming the holes which will be used to rivet on steel plates, 1-1/8" thick either side of the rim. These plates overlap the segment joints.

The article says that the works, on average, complete one segmental wheel every other day. An accompanying drawing shows that the spokes are hollow, but with a wall thickness of 3" in a radial cross-section.

This next photo just looked interesting - not exactly a flywheel, but the 'spider' for the generator, it fits alongside the flywheel (not yet fitted). They are using electric-driven hydraulic presses to fit the spider onto the shaft. (5000hp engine)

And here is a photo of one of the engines in a more complete state.