kielbasavw

Aluminum

- Joined

- Feb 25, 2013

- Location

- california

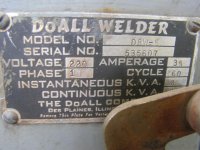

Can anyone help with any info on this blade welder? It's attached to what I believe is a pre doall saw. I'm not sure on anything about it. It does look like it has some sort of Australian plug. Maybe 220v?

. Ok, mine is close, but not an exact match, its an old D0-All. Looks like maybe someone robbed the grinder off yours.

. Ok, mine is close, but not an exact match, its an old D0-All. Looks like maybe someone robbed the grinder off yours.