THax

Aluminum

- Joined

- May 9, 2007

- Location

- Wellsville, Kansas

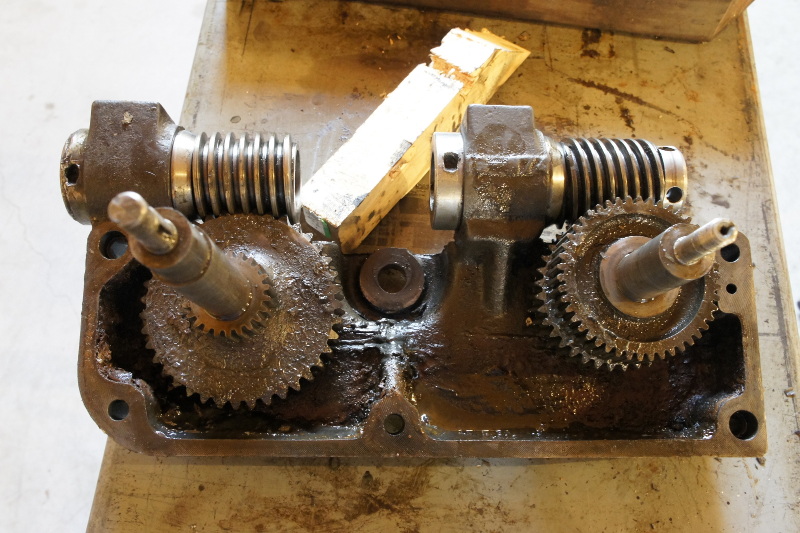

Below should be before and after pics of the 16 X 8 Conehead I picked up about 10 years ago. From what I've read here, I surmise it to be a late '29. (Hendeyman, If you can shed any further light on the history I'd sure appreciate it!)

Overall, I'd say this lathe is in pretty good shape. Heavy loading from the tailstock on occasion does reveal the beginnings of the Hendey spindle thrust issue, but that will be a project for another time.

The problem at present is the power cross feed. After engaging it I cannot get it to dis-engage! Of course, this locks up the manual feed. I seem to recall reading something about this before, but can't seem to find much about it. An exploded view of the apron assembly would be damned handy, but doesn't seem to exist. Has anyone else run across this problem? Anyone know of a quick trick to get this thing to release! I figure an apron teardown is in my future, but I'd like to at least have my lathe 90% functional in the meantime

Overall, I'd say this lathe is in pretty good shape. Heavy loading from the tailstock on occasion does reveal the beginnings of the Hendey spindle thrust issue, but that will be a project for another time.

The problem at present is the power cross feed. After engaging it I cannot get it to dis-engage! Of course, this locks up the manual feed. I seem to recall reading something about this before, but can't seem to find much about it. An exploded view of the apron assembly would be damned handy, but doesn't seem to exist. Has anyone else run across this problem? Anyone know of a quick trick to get this thing to release! I figure an apron teardown is in my future, but I'd like to at least have my lathe 90% functional in the meantime