Bruce Johnson

Stainless

- Joined

- Jan 8, 2006

- Location

- Burbank, CA USA

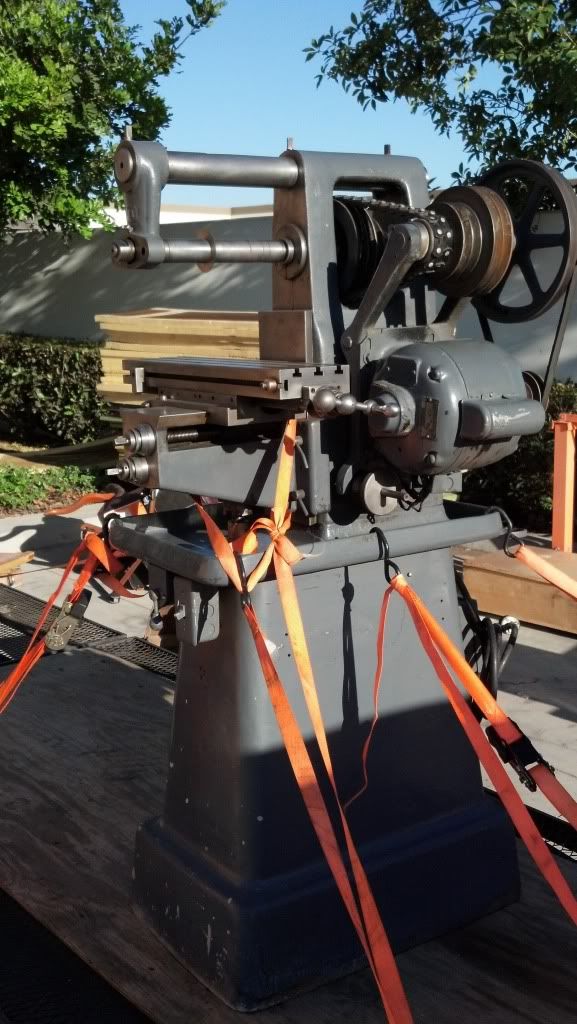

I just acquired another little Diamond horizontal mill. I have three of them now. It came from small machine shop that specializes in gear cutting. They were shrinking down to a smaller building and needed to get rid of a couple of machines. So they gave this mill to a neighbor shop, a guitar building friend of mine. He stored it for a while, but had no real use for it, so he gave it to me. How could I refuse?

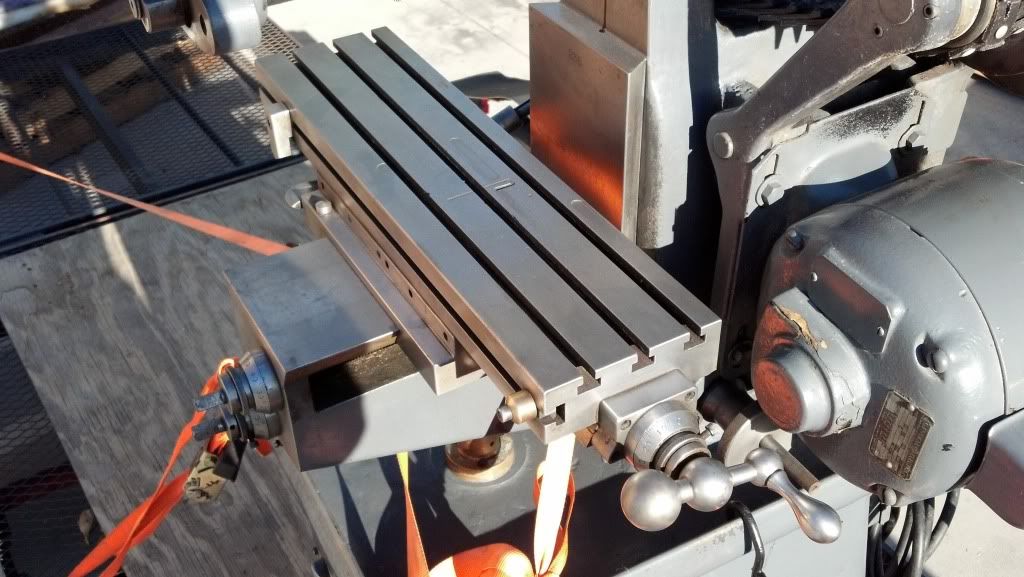

The name plate is missing, but it appears to be a M-20, like my other two. But there are a few interesting differences. Note the rounded cast iron end caps on the ends of the table. They are obviously made for collecting coolant runoff. My other two don't have those. They have a simple plate that retains the leadscrew and dial. Maybe these rounded caps were an option?

This machine was converted to a roller chain primary drive from the motor to the jack shaft, with a sheet metal cover over it. It normally is a V-belt drive back there. The motor is a cool old 2-speed monster, that switches between 1800 and 900 rpm. It's made by Ray Wrey, Los Angeles, who I've never heard of. It's 3/4 HP, 3 phase.

Another curiosity is the pair of roller chain sprockets in the secondary drive to the spindle. Huh? At first I assumed that they were a later modification, but they fit into the assembly and casting very neatly, as if it's a factory installation. Maybe the whole motor and roller chain drive rig were a factory option? Everything except the sheet metal cover.

On the other side is a neat home built electric power feed for the table. Normally, there's a V-belt drive from the spindle, which drives the U-jointed shaft up to the table. Somebody fitted a mysterious little gearbox with a separate motor. Note the interesting quadrant lever and cable that controls it. It may be a variable speed gearbox. I'll have to fire it up and see what it does.

Overall, the mill appears to be in good shape. It apparently was in use up until recently, cutting some small slots. It's covered with sawdust from sitting in my buddy's shop. I'm going to clean it up thoroughly and build it a good wooden pallet jack-able base. Then plug it in and put it to work. It doesn't appear to need any obvious repairs.

The name plate is missing, but it appears to be a M-20, like my other two. But there are a few interesting differences. Note the rounded cast iron end caps on the ends of the table. They are obviously made for collecting coolant runoff. My other two don't have those. They have a simple plate that retains the leadscrew and dial. Maybe these rounded caps were an option?

This machine was converted to a roller chain primary drive from the motor to the jack shaft, with a sheet metal cover over it. It normally is a V-belt drive back there. The motor is a cool old 2-speed monster, that switches between 1800 and 900 rpm. It's made by Ray Wrey, Los Angeles, who I've never heard of. It's 3/4 HP, 3 phase.

Another curiosity is the pair of roller chain sprockets in the secondary drive to the spindle. Huh? At first I assumed that they were a later modification, but they fit into the assembly and casting very neatly, as if it's a factory installation. Maybe the whole motor and roller chain drive rig were a factory option? Everything except the sheet metal cover.

On the other side is a neat home built electric power feed for the table. Normally, there's a V-belt drive from the spindle, which drives the U-jointed shaft up to the table. Somebody fitted a mysterious little gearbox with a separate motor. Note the interesting quadrant lever and cable that controls it. It may be a variable speed gearbox. I'll have to fire it up and see what it does.

Overall, the mill appears to be in good shape. It apparently was in use up until recently, cutting some small slots. It's covered with sawdust from sitting in my buddy's shop. I'm going to clean it up thoroughly and build it a good wooden pallet jack-able base. Then plug it in and put it to work. It doesn't appear to need any obvious repairs.

So now that the Benchmaster sold, I have to figure out how to get the Diamond into my shop (and off my trailer). The overarm on the Diamond is 2" diameter so I will have to devise a spacer to fit the 2 1/4" opening on the Rusnok. The diamond has a larger footprint, but I will be saving space by consolidating the two.

So now that the Benchmaster sold, I have to figure out how to get the Diamond into my shop (and off my trailer). The overarm on the Diamond is 2" diameter so I will have to devise a spacer to fit the 2 1/4" opening on the Rusnok. The diamond has a larger footprint, but I will be saving space by consolidating the two.