phat daddy:

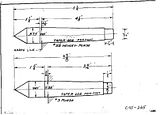

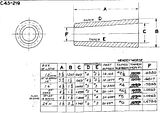

About 6 to 8 weeks ago, I sent out a drawing of the bushing used in the headstock to

allow the tailstock center to be used in the headstock spindle. It seems that I now have to send out a print of the #3 MH taper center for the tailstock. I have a drawing that

shows the #3 MT center next to the MH taper for comparison. The first time you look at

the drawing you may not see the difference, but just keep looking and you will see it.

While the Morse Taper was available in several "half sizes", Hendey used the 2-1/2, 3-1/2

4-1/2 and 5-1/2 on a regular basis. John's comment about not having any information

about the MorseHendey tapers is very understandable, they were never published. When

I make a center or a sleeve in either the Morse taper or Morse-Hendey taper, I have the

advantage of a set of ring and plug gages for both types of taper that makes the job a

lot easier. Since most of you will be making one or two off of these centers, just work to

the gage lines shown and you should get a perfect fit. One more thing, Hendey did supply

the Jarno taper and centers on some lathes. If you need a copy of the MH taper drawing,

leave you name and a fax number and I will send it out. I can also send it to one person,

who can distribute it to the rest of you.

Hendeyman