Asquith

Diamond

- Joined

- Mar 3, 2005

- Location

- Somerset, UK

Some PM members are only interested in machine tools.

Some are interested in steam engines.

Some, who are interested in neither, will find little to appeal to them here, but they are probably otherwise occupied, typing furiously into the ‘Manufacturing’ forum at this very moment.

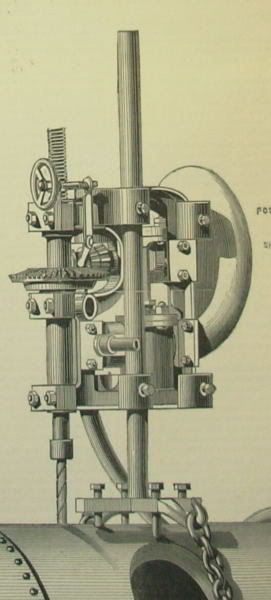

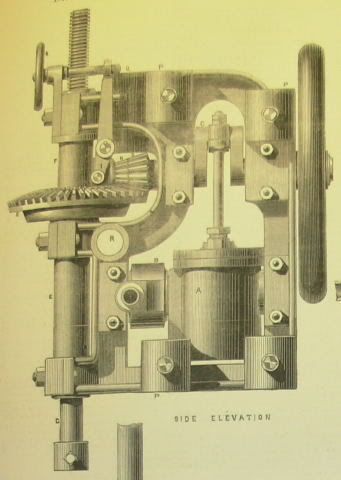

Made by Brown, Wilson & Co., Vauxhall Ironworks, London, c.1867.

It had a reversible single oscillating cylinder. Steam was supplied through an India Rubber hose. Compressed air could be used as an alternative. No doubt the operator, given the choice of air or steam in a rubber pipe at close proximity to his face would favour the former, while his boss would be keen on the farthing per year saved by not having to wastefully use another steam engine to compress air. On the other hand, a burst steam hose has to be replaced at great expense. India Rubber doesn't grow on trees, you know. Or does it?

Two bevel pinions were located on the end of the crankshaft. One was fixed to the crankshaft and turned the spindle. The other, smaller, pinion was fitted loose outboard of this. The two driven bevel gears normally whizzed round together. However, the small handwheel pressed the loose pinion into service (friction drive). This turned its own bevel gear at a slightly faster speed than the main one (different ratios). This caused the inner vertical spindle to descend (because the smaller bevel wheel was threaded to act like a nut on the inner spindle).

The drill was provided with bits and pieces to allow it to be wall-mounted and used like a radial arm drill.

Much was made of the advantages of a powered portable drill. The traditional ratchet brace was regarded as wasting a skilled fitter’s time, while the employment of apprentices to do the work usually resulted in a fitter having to correct the mess, while labourers tended to do a good job but were slow. Ratchet drills ‘afford the readiest excuse for lazy workmen and apprentices skulking and idling away their time. A seat and the monotonous click of the ratchet brace, with the gentlest pressure of the screw, is, with such men, the greatest luxury of the erecting shop….’. So said ‘The Engineer’ in 1868.

The steam drill’s exhaust beat gave the foreman audible indication that drilling was proceeding, and all was well with the world.

Some are interested in steam engines.

Some, who are interested in neither, will find little to appeal to them here, but they are probably otherwise occupied, typing furiously into the ‘Manufacturing’ forum at this very moment.

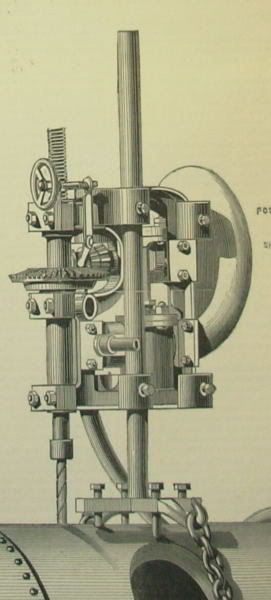

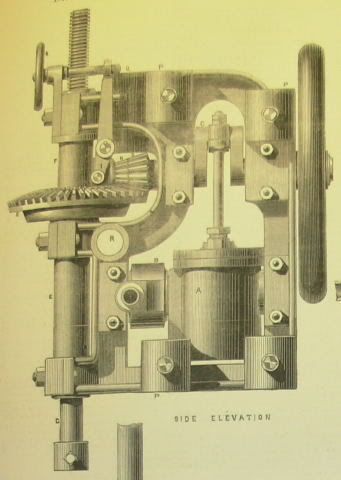

Made by Brown, Wilson & Co., Vauxhall Ironworks, London, c.1867.

It had a reversible single oscillating cylinder. Steam was supplied through an India Rubber hose. Compressed air could be used as an alternative. No doubt the operator, given the choice of air or steam in a rubber pipe at close proximity to his face would favour the former, while his boss would be keen on the farthing per year saved by not having to wastefully use another steam engine to compress air. On the other hand, a burst steam hose has to be replaced at great expense. India Rubber doesn't grow on trees, you know. Or does it?

Two bevel pinions were located on the end of the crankshaft. One was fixed to the crankshaft and turned the spindle. The other, smaller, pinion was fitted loose outboard of this. The two driven bevel gears normally whizzed round together. However, the small handwheel pressed the loose pinion into service (friction drive). This turned its own bevel gear at a slightly faster speed than the main one (different ratios). This caused the inner vertical spindle to descend (because the smaller bevel wheel was threaded to act like a nut on the inner spindle).

The drill was provided with bits and pieces to allow it to be wall-mounted and used like a radial arm drill.

Much was made of the advantages of a powered portable drill. The traditional ratchet brace was regarded as wasting a skilled fitter’s time, while the employment of apprentices to do the work usually resulted in a fitter having to correct the mess, while labourers tended to do a good job but were slow. Ratchet drills ‘afford the readiest excuse for lazy workmen and apprentices skulking and idling away their time. A seat and the monotonous click of the ratchet brace, with the gentlest pressure of the screw, is, with such men, the greatest luxury of the erecting shop….’. So said ‘The Engineer’ in 1868.

The steam drill’s exhaust beat gave the foreman audible indication that drilling was proceeding, and all was well with the world.