rivett608

Diamond

- Joined

- Oct 25, 2002

- Location

- Kansas City, Mo.

I fessed up that it was I that bought this.... well it came today..... HUMMMMMMM

Here was the original post about it...

http://www.practicalmachinist.com/vb/antique-machinery-history/e-bay-funny-203609/

I would like to thank wippin' boy for pointing it out.... now I can blame him for this puzzle

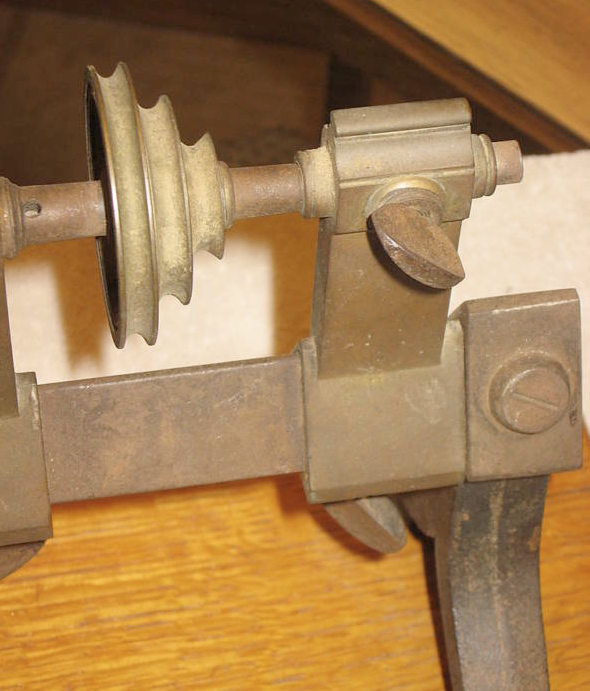

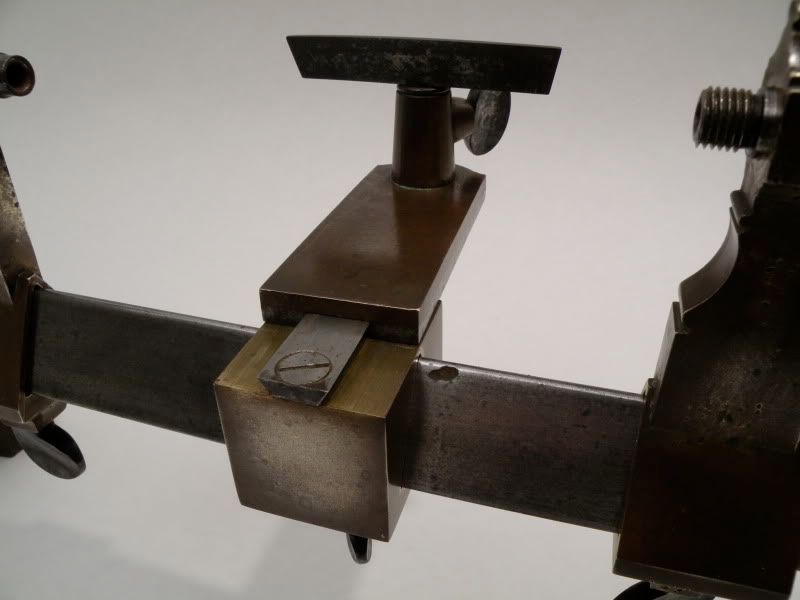

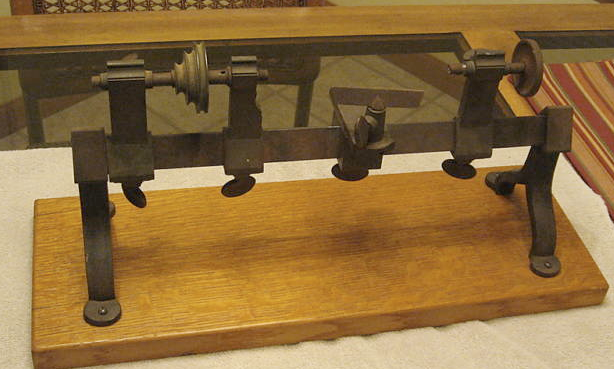

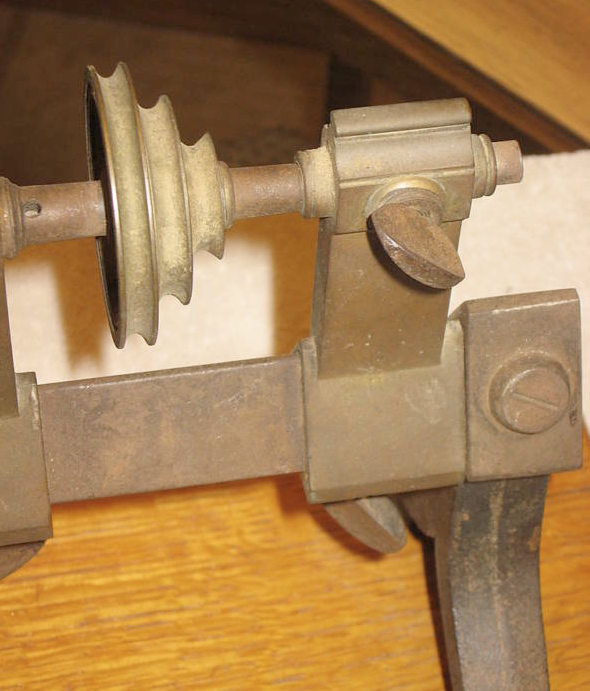

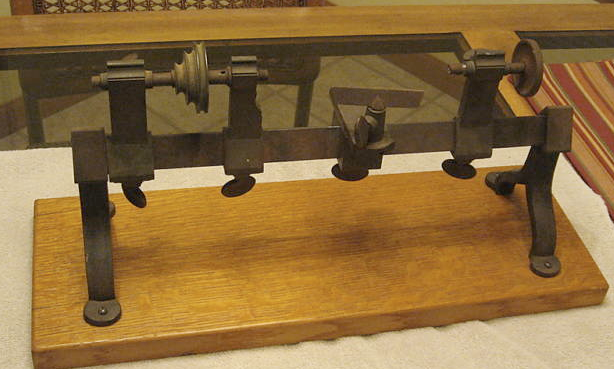

On first look it appears much nicer than I thought! It is VERY finely made, the workmanship is fantastic..... I can not tell from the first quick look how old it is. I will take it apart and study it carefully looking for tool marks to tell me if it is hand or machine made. It is much smaller than I imagined (this is OK with me)....... more later but her are some of the photos from ebay... I thought I would post before they disappeared. And the board it is mounted does appear to be a nice piece of solid oak.......

I hope to able to answer all my questions and yours......

BTW I did see that it has a tapered front bearing and the back end of the spindle is very interesting....

Here was the original post about it...

http://www.practicalmachinist.com/vb/antique-machinery-history/e-bay-funny-203609/

I would like to thank wippin' boy for pointing it out.... now I can blame him for this puzzle

On first look it appears much nicer than I thought! It is VERY finely made, the workmanship is fantastic..... I can not tell from the first quick look how old it is. I will take it apart and study it carefully looking for tool marks to tell me if it is hand or machine made. It is much smaller than I imagined (this is OK with me)....... more later but her are some of the photos from ebay... I thought I would post before they disappeared. And the board it is mounted does appear to be a nice piece of solid oak.......

I hope to able to answer all my questions and yours......

BTW I did see that it has a tapered front bearing and the back end of the spindle is very interesting....