rsal

Aluminum

- Joined

- Mar 8, 2005

- Location

- Danville IN

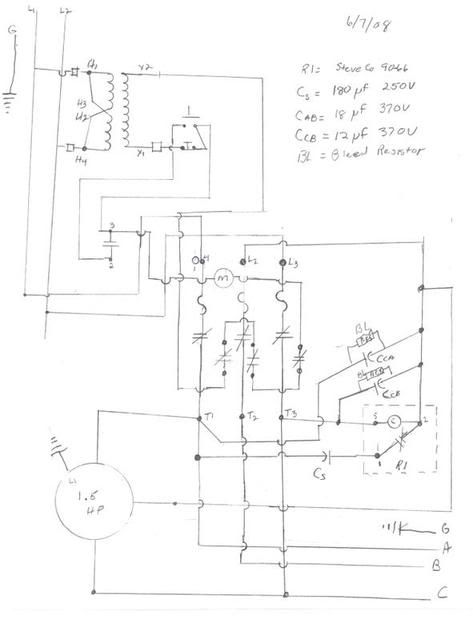

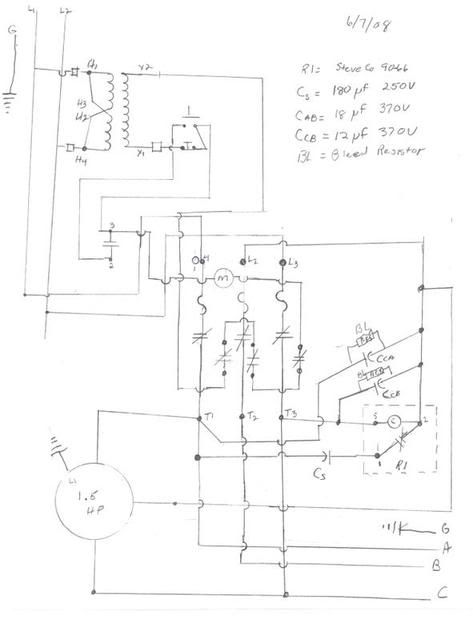

I have been reading the board and have answered most of my questions on a rpc. I have a Hardinge DV-59 with a 3/4\3/8 hp dual speed motor that I want to run with a rpc. I am looking at using a potential relay (steveco 90-66) and a 1 1/2 hp motor that a friend gave me. I do have some questions that I need answered.

How do you calculate the resistor value to use as a bleed resistor?

If I understand using a motor starter (Square D 8536) you are to size the heaters for the load only. Is this correct even on the rpc?

I have drawn a diagram for wiring the electrical box and would like to make sure I have it right before I do the wiring. If it needs touching up, let me know what and why as I am learning as I go with machinery. I do understand the basics of electricity but do not deal with it daily (like I do drainage systems) so I want to be certain it is correct before I go forward. I do have a friend that works with electricity daily but we work different shifts and do not get together enough for me to pick his brain on this.

Anyway, if everyone could look at this and comment, I would be greatful.

rsal

How do you calculate the resistor value to use as a bleed resistor?

If I understand using a motor starter (Square D 8536) you are to size the heaters for the load only. Is this correct even on the rpc?

I have drawn a diagram for wiring the electrical box and would like to make sure I have it right before I do the wiring. If it needs touching up, let me know what and why as I am learning as I go with machinery. I do understand the basics of electricity but do not deal with it daily (like I do drainage systems) so I want to be certain it is correct before I go forward. I do have a friend that works with electricity daily but we work different shifts and do not get together enough for me to pick his brain on this.

Anyway, if everyone could look at this and comment, I would be greatful.

rsal