bunnybungo

Plastic

- Joined

- Jan 20, 2008

- Location

- Manila, Philippines

Good day to all,

I would like to ask how will I know the HP rating and Electrical information of an electric motor?

Its name plate has been removed from its body

If it is possible, What particular info is needed?

Knowing the dimension of the motor and diameter of the shafting may help in determining those info?

Many thanks to all!!!

I would like to ask how will I know the HP rating and Electrical information of an electric motor?

Its name plate has been removed from its body

If it is possible, What particular info is needed?

Knowing the dimension of the motor and diameter of the shafting may help in determining those info?

Many thanks to all!!!

Last edited:

Dave

Dave

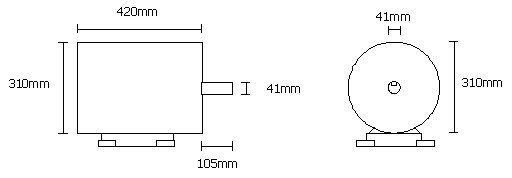

The 41mm shaft diameter you show equates to 1 5/8”. Follow that through the tables on the Gates web site:

The 41mm shaft diameter you show equates to 1 5/8”. Follow that through the tables on the Gates web site: