handscrape

Aluminum

- Joined

- Dec 4, 2011

- Location

- Canada

Hi Guys,

I got my TL-2 in a couple of weeks ago and wanted to post some pictures for eveyone to see.

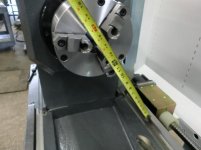

I was looking at pics online before I got it and couldn't find any with measurements, hence the measuring tape in the photo.

The biggest thing I was curious about was how big it could swing. Approx 28" dia if you remove the cover.

They advertised it as a 16" x 48" machine.

Havent used the machine yet but my idea was to fill in the gap in our shop between manual turning and full cnc.

Some things I like, other things not to sure about but I think it will serve its purpose.

thanks,

h.s.

I got my TL-2 in a couple of weeks ago and wanted to post some pictures for eveyone to see.

I was looking at pics online before I got it and couldn't find any with measurements, hence the measuring tape in the photo.

The biggest thing I was curious about was how big it could swing. Approx 28" dia if you remove the cover.

They advertised it as a 16" x 48" machine.

Havent used the machine yet but my idea was to fill in the gap in our shop between manual turning and full cnc.

Some things I like, other things not to sure about but I think it will serve its purpose.

thanks,

h.s.