bradjacob

Titanium

- Joined

- Nov 18, 2008

- Location

- Easton, PA

Hi all -

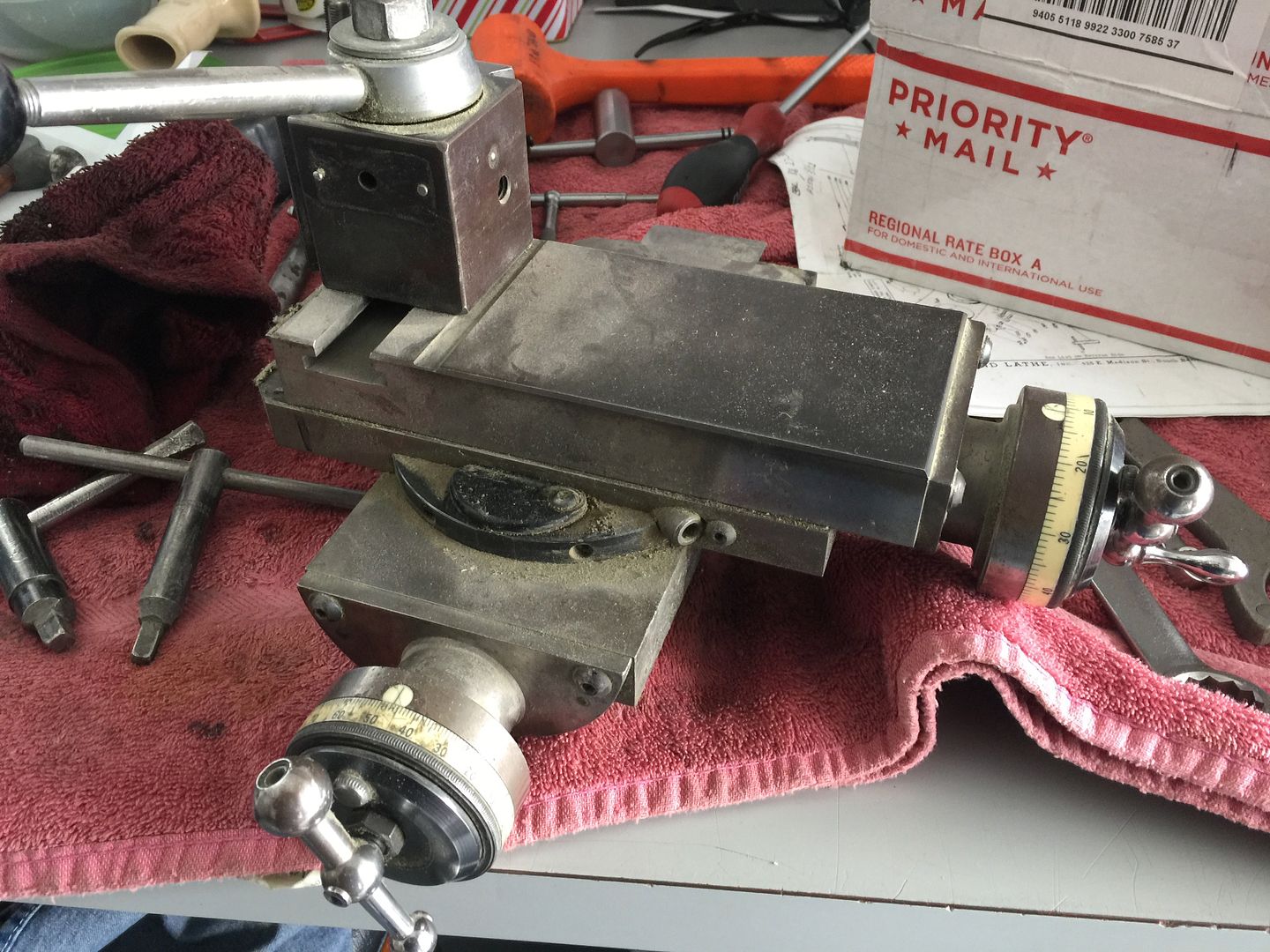

I just bought a decent DV59.

I plan to buy a turret and cross slide for it, so it'll be a "DVSM"-59 (haha)

I have 3 questions for the hardinge experts:

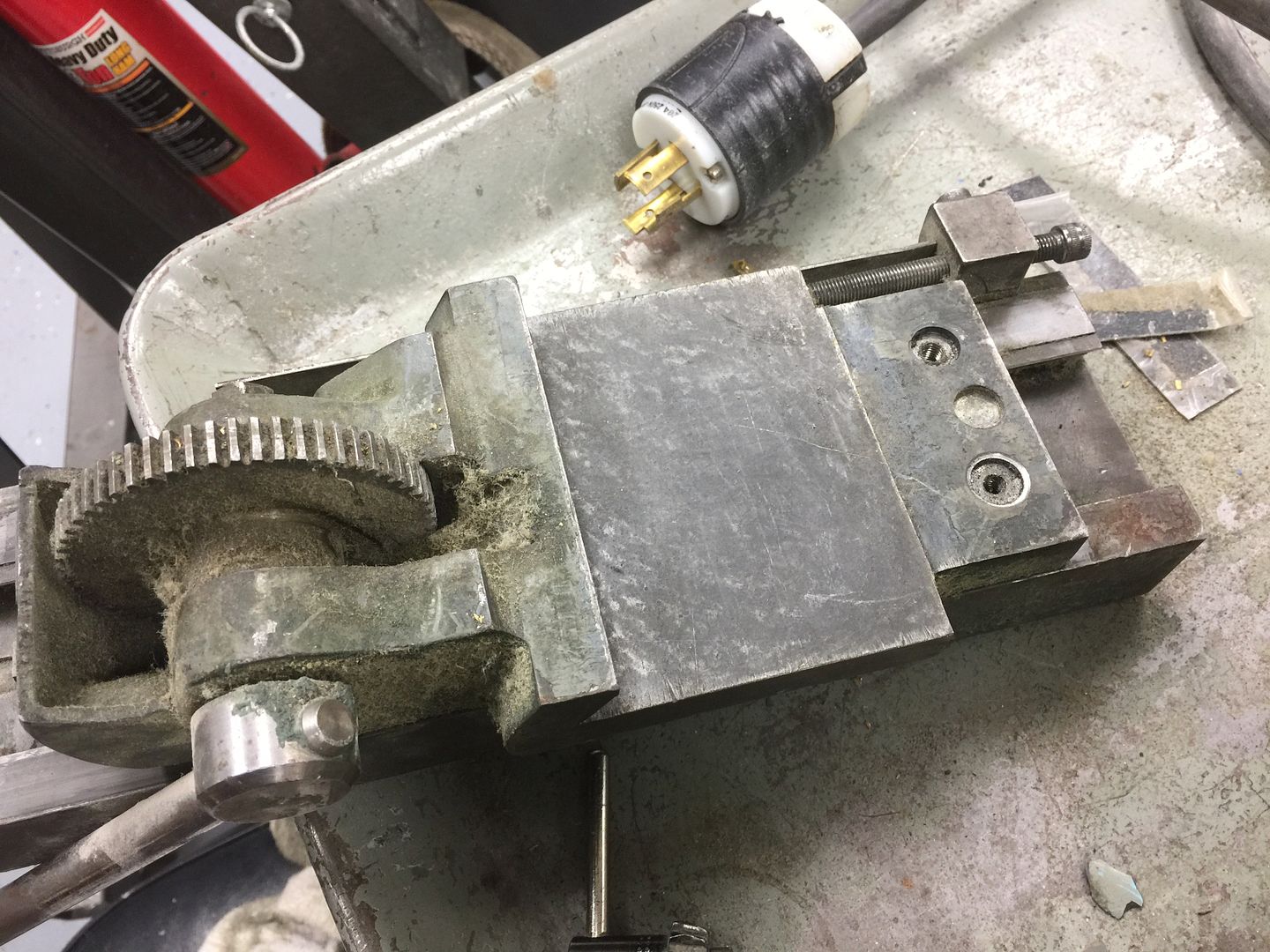

1. Was taking apart the compound dials and got it all disassembled, EXCEPT for the compound. Everything is removed, except for the two castings, they're held by two binder clamps, that I can not figure out how to remove. Anyone know how to do this?

2. Does hardinge sell new lead screws or nuts?

3. How do I find the serial number and date the machine?

I'm VERY happy to be a new member of the Hardinge owners family

I just bought a decent DV59.

I plan to buy a turret and cross slide for it, so it'll be a "DVSM"-59 (haha)

I have 3 questions for the hardinge experts:

1. Was taking apart the compound dials and got it all disassembled, EXCEPT for the compound. Everything is removed, except for the two castings, they're held by two binder clamps, that I can not figure out how to remove. Anyone know how to do this?

2. Does hardinge sell new lead screws or nuts?

3. How do I find the serial number and date the machine?

I'm VERY happy to be a new member of the Hardinge owners family