Shopteach1

Plastic

- Joined

- Jan 8, 2016

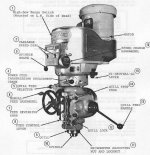

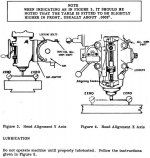

I am a highschool metal work instructor, we have just managed to scrape some money together to replace the old combination horiz/vertical mill with a new First LC 1-1/2 42" x 9" vertical mill (Bridgeport clone). Pretty darned happy about that, I haven't been able to use a decent mill since I left the trades 20 years ago to become a shop teacher (we had Ex cello's in the shop I worked in). Now the bad part, I was making up some plywood table covers when I discovered the quill feed locked up solid. The quill is in the fully up position, the micrometer stop nut is clear and the quill lock is loose. It appears that someone managed to get the quill feed engaged and it would appear it was fed upwards. With the quill feed transmission disengaged the spindle turns freely, but the quill she is locked. With quill feed transmission engaged, it sounds like the quill feed clutch is disengaging as it is making nasty clacking sounds.

I could not manually activate the feed kick off lever, I unscrewed the screw holding the kick off lever at the bottom and it released, but the quill is still tight.

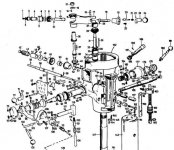

I removed the cover for the feed clutch mechanism, and according to a video I viewed, it seems like the clutch should slide out, but it seems stuck in place and I haven't applied any force as I am unsure of appropriate procedure.

I have called the supplier of the mill, but the tech has not returned my call yet. The supplier is a days travel and a ferry ride away, I am hoping for warranty, but I am not holding my breath as I can't exactly explain what happened as so far no one has fessed up to tinkering with the feed mechanism.

Further, our maintenance mechanic just went off on medical and will be gone for at least 4 weeks. I suspect if this is to be fixed reasonably quickly, I will be fixing it.

Any suggestions where to start would be mucho appreciated!

Thank you,

Alan

I could not manually activate the feed kick off lever, I unscrewed the screw holding the kick off lever at the bottom and it released, but the quill is still tight.

I removed the cover for the feed clutch mechanism, and according to a video I viewed, it seems like the clutch should slide out, but it seems stuck in place and I haven't applied any force as I am unsure of appropriate procedure.

I have called the supplier of the mill, but the tech has not returned my call yet. The supplier is a days travel and a ferry ride away, I am hoping for warranty, but I am not holding my breath as I can't exactly explain what happened as so far no one has fessed up to tinkering with the feed mechanism.

Further, our maintenance mechanic just went off on medical and will be gone for at least 4 weeks. I suspect if this is to be fixed reasonably quickly, I will be fixing it.

Any suggestions where to start would be mucho appreciated!

Thank you,

Alan