ChipChaff

Cast Iron

- Joined

- Dec 15, 2007

- Location

- Mid-Wisconsin

Hi all,

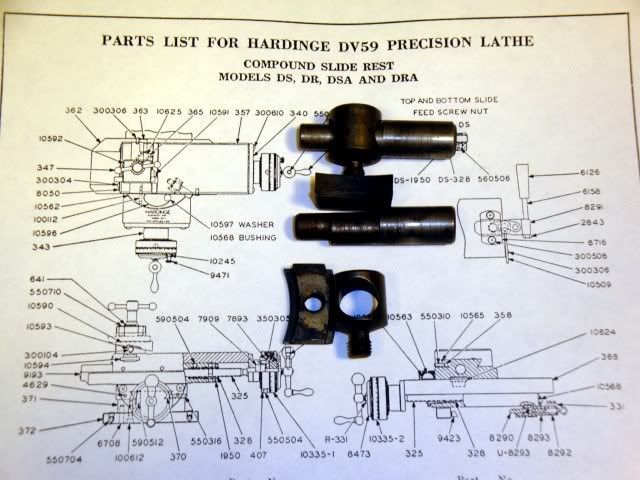

I just bought (stripped, repainted, and tooled - thanks to this site) a Hardinge DV59 with compound cross slide from a school via a machinery dealer - who was very fair. It works beautifully but I've had a problem in locking the compound to the cross slide.

Please forgive me if I don't use the correct terminology - I just barely passed Plastic - but there are two hex headed plugs with three eccentric planes each that lock the top compound slide to the bottom cross slide. The one on the left side of the compound crank locks in nice and tight and stands proud when it's snugged in. The one on the right (back) side rotates freely and the head of the plug sinks into the hole without binding at any point. It's not the plugs as I've swapped them and each locks in tightly on the left side hole and neither locks in on the right and there's no galling or wear apparent on either plug. Before I start tearing it apart, do you think the assembly is missing a part or is there some alignment trick I'm not seeing, or do you thing some ham handed student just wallowed out the locking surfaces in the hole? If this is a common problem, is there a common fix? I'd hate to have to find another one - I paid less for the lathe and tooling than I've seen compounds listed for on e(yech)Bay.

Thanks,

Chip

I just bought (stripped, repainted, and tooled - thanks to this site) a Hardinge DV59 with compound cross slide from a school via a machinery dealer - who was very fair. It works beautifully but I've had a problem in locking the compound to the cross slide.

Please forgive me if I don't use the correct terminology - I just barely passed Plastic - but there are two hex headed plugs with three eccentric planes each that lock the top compound slide to the bottom cross slide. The one on the left side of the compound crank locks in nice and tight and stands proud when it's snugged in. The one on the right (back) side rotates freely and the head of the plug sinks into the hole without binding at any point. It's not the plugs as I've swapped them and each locks in tightly on the left side hole and neither locks in on the right and there's no galling or wear apparent on either plug. Before I start tearing it apart, do you think the assembly is missing a part or is there some alignment trick I'm not seeing, or do you thing some ham handed student just wallowed out the locking surfaces in the hole? If this is a common problem, is there a common fix? I'd hate to have to find another one - I paid less for the lathe and tooling than I've seen compounds listed for on e(yech)Bay.

Thanks,

Chip