jw714

Plastic

- Joined

- Oct 7, 2006

- Location

- East Central Florida

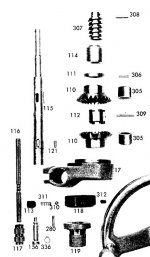

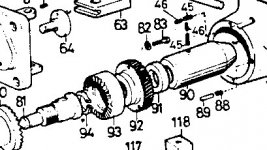

I recently bought a series 1 step pulley machine that had a broken downfeed. I disasembled the geartrain and replaced a lot of the parts, worm gear cradle,cluster shaft,worm gear feed shaft. After assembling the worm cradle it seems to bind up the worm feed shaft when I tighten the setscrew that holds the brass bushing in the cradle. This setscrew also sets the backlash on the feed pinion. I'm not sure if I have a problem or not. Even with the setscrew pretty tight I can still turn the assembly with my fingers. I f I tighten the setscrew real tight it will bind the shaft so I can't turn it. Any ideas? BTW I reinstalled the new shaft assembly in the old cradle and had the same results. Thanks, John