cinematechnic

Cast Iron

- Joined

- Apr 11, 2005

- Location

- Walnut Creek, CA

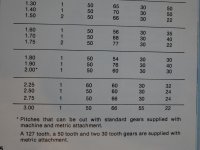

Last evening I was setting up to cut a M24 x 3.0 thread (in soft aluminum) for a one off project. Then I looked at the threading chart and had to stop. According to the Hardinge metric threading chart, a 55T idler gear pair is used to cut 3mm pitch. I only have one 55T gear.

On (mercifully in L.A.) short drive home, I got to thinking: Why was I convinced that I could do this? Then I realized - for 0.5, 1 and 2mm pitches, the gear combination is the same and you switch the threading knob position 3 for 0.5mm, 2 for 1.0mm and 1 for 2mm.

I had successfully cut 0.75mm thread many times (I mostly do fine pitch threads). The gear combo (assuming 127T gear on shaft with 66T gear) for 0.75 / 1.5mm pitch is:

50 fist gear

66 2nd gear on stud

30 idler gear

22 screw gear

So why does that combination NOT work for 3.0mm pitch with the threading knob on "1"?

I studied the threading chart and in MOST cases, there is a 1:2:4 relationship to pitches that are cut with the threading knob in positions 1-2-3. But this logic does break down for a few pitch combinations. The ones I could find in a quick search are 2.5 and 1.25mm, and 0.4 and 0.8 mm where the gear combos are not the same.

Update: I did some further research and it seems that the idler gear does not affect the overall gear ratio. But I'm still confused why a gear setup that -should- cut 3mm pitch doesn't work. What was the reason for changing to the 55T idler?

BTW, I have a M24 x 3 die so as long as I can get some starter threads on that piece of Al I can finish the job with the die.

On (mercifully in L.A.) short drive home, I got to thinking: Why was I convinced that I could do this? Then I realized - for 0.5, 1 and 2mm pitches, the gear combination is the same and you switch the threading knob position 3 for 0.5mm, 2 for 1.0mm and 1 for 2mm.

I had successfully cut 0.75mm thread many times (I mostly do fine pitch threads). The gear combo (assuming 127T gear on shaft with 66T gear) for 0.75 / 1.5mm pitch is:

50 fist gear

66 2nd gear on stud

30 idler gear

22 screw gear

So why does that combination NOT work for 3.0mm pitch with the threading knob on "1"?

I studied the threading chart and in MOST cases, there is a 1:2:4 relationship to pitches that are cut with the threading knob in positions 1-2-3. But this logic does break down for a few pitch combinations. The ones I could find in a quick search are 2.5 and 1.25mm, and 0.4 and 0.8 mm where the gear combos are not the same.

Update: I did some further research and it seems that the idler gear does not affect the overall gear ratio. But I'm still confused why a gear setup that -should- cut 3mm pitch doesn't work. What was the reason for changing to the 55T idler?

BTW, I have a M24 x 3 die so as long as I can get some starter threads on that piece of Al I can finish the job with the die.

Last edited: