alex3811

Plastic

- Joined

- Jun 18, 2014

- Location

- Switzerland

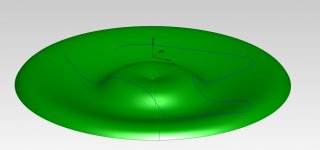

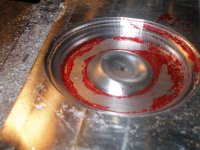

Ok, after all... after two months of trying with featurecam

is there ANY CAM which can create curve driven toolpath in 3D???

is there ANY CAM which can create curve driven toolpath in 3D???