ewlsey

Diamond

- Joined

- Jul 14, 2009

- Location

- Peoria, IL

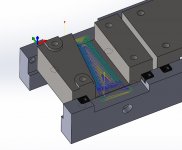

Can anyone tell me how to change the starting side for an adaptive clearing operation? I am cutting a sort of slot. I want it to start at the bigger end to maximize chip clearing. It always starts at the +Y side.

I have tried the start point features in the linking tab, but it never changes the side it starts on.

Any ideas?

I have tried the start point features in the linking tab, but it never changes the side it starts on.

Any ideas?