I got VisualCAM from MECSoft a couple of years ago when I first got my Journeyman 325, thinking I'd need some decent CAM software to make good use of it.

Turns out I can do most of what I need to do on a daily basis from the control using conversational programming, so learning VisualCAM hasn't been a high priority.

I chose it because it had a plug-in for Alibre Design, which I use for my 3D modeling, and it seemed to be the most integrated solution for Alibre. I paid a total of about $1600 for software licenses - and then they discontinued the plug-in, so I'm stuck exporting from Alibre and importing into VisualCAM and manually changing units each time.

Every time I try to get comfortable using VisualCAM, I just end up more frustrated and angry. The program constantly gives useless error messages. "No valid data found. Internal algorithm failure!" is its favorite, and seems to be the catch-all for any problem generating tool paths.

It fails for the stupidest reasons. It will let you define a tool with the flute length equal to the shoulder length and doesn't give any warnings, and in fact that seems to make perfect sense for something like my corncob rougher in a DA180 collet where the flutes extend all the way to the face of the collet nut and then some. It doesn't restrict the entry, though, and it doesn't give a useful error message - it just dies.

There are dozens of warts like this. The program feels clunky and brittle. The way it handles configuring speeds and feeds seems completely counter-intuitive.

I'm a relative novice at machining and I wonder if maybe my expectations are wrong, but on the other hand I've been a professional programmer for most of my career and this stuff would not fly anywhere I've worked.

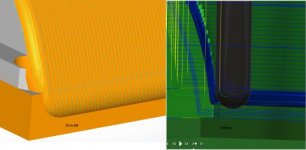

Just for kicks I installed a trial of Fusion 360 and without reading *any* documentation I was able to generate a working program for my Delta 20 in maybe 10 minutes. Like the Roland Modela CAM program, the only other one I've really used, it shows nice diagrams and tips for each parameter, and the error messages are useful and meaningful. Generating a program in RML for my Roland MDX-20 mill took a few more minutes of playing with coordinate systems, but that was fairly painless too.

Does VisualCAM get better? Is it a decent program once you get through all of the pain of setting up your tool library and conditioning yourself not to do any of the things that make it crash? Or is it really as bad as it seems? If I hadn't already sunk so much money into it I'd drop it in a heartbeat. They want $300/year for a maintenance subscription and $400 for upgrades. For $300/year I could just get Fusion 360.

Scott

Turns out I can do most of what I need to do on a daily basis from the control using conversational programming, so learning VisualCAM hasn't been a high priority.

I chose it because it had a plug-in for Alibre Design, which I use for my 3D modeling, and it seemed to be the most integrated solution for Alibre. I paid a total of about $1600 for software licenses - and then they discontinued the plug-in, so I'm stuck exporting from Alibre and importing into VisualCAM and manually changing units each time.

Every time I try to get comfortable using VisualCAM, I just end up more frustrated and angry. The program constantly gives useless error messages. "No valid data found. Internal algorithm failure!" is its favorite, and seems to be the catch-all for any problem generating tool paths.

It fails for the stupidest reasons. It will let you define a tool with the flute length equal to the shoulder length and doesn't give any warnings, and in fact that seems to make perfect sense for something like my corncob rougher in a DA180 collet where the flutes extend all the way to the face of the collet nut and then some. It doesn't restrict the entry, though, and it doesn't give a useful error message - it just dies.

There are dozens of warts like this. The program feels clunky and brittle. The way it handles configuring speeds and feeds seems completely counter-intuitive.

I'm a relative novice at machining and I wonder if maybe my expectations are wrong, but on the other hand I've been a professional programmer for most of my career and this stuff would not fly anywhere I've worked.

Just for kicks I installed a trial of Fusion 360 and without reading *any* documentation I was able to generate a working program for my Delta 20 in maybe 10 minutes. Like the Roland Modela CAM program, the only other one I've really used, it shows nice diagrams and tips for each parameter, and the error messages are useful and meaningful. Generating a program in RML for my Roland MDX-20 mill took a few more minutes of playing with coordinate systems, but that was fairly painless too.

Does VisualCAM get better? Is it a decent program once you get through all of the pain of setting up your tool library and conditioning yourself not to do any of the things that make it crash? Or is it really as bad as it seems? If I hadn't already sunk so much money into it I'd drop it in a heartbeat. They want $300/year for a maintenance subscription and $400 for upgrades. For $300/year I could just get Fusion 360.

Scott