vegard

Aluminum

- Joined

- Jan 28, 2006

- Location

- San Diego, CA

Hi,

I just put a kitamura MyCenter 1 in my garage, and I am trying to get it tooled up.

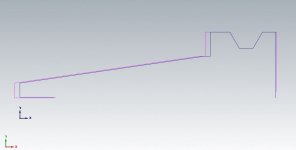

Looks like there are 2 types of BT35 with slightly different pull stud bores and the v-flange slightly different? I just learned this while trying to use my brand new holders...

I got 4 nikken sk10 collet chucks and a couple centaur ER16's that are the wrong type (looks like MAS BT35 vs regular BT35) These are brand new...

What gives here?? I guess there are machines out there that use this other spec of BT35?

Anyone know a source for ER chucks with the old BT35 to fit my kitamura? I am not even sure how to tell which one I am looking at online, as no one seems to differentiate the two specs, but so far 100% of what I have bought new has been wrong....

See here http://www.lyndexnikken.com/cp/303A/E189.pdf

Thanks

Vegard

I just put a kitamura MyCenter 1 in my garage, and I am trying to get it tooled up.

Looks like there are 2 types of BT35 with slightly different pull stud bores and the v-flange slightly different? I just learned this while trying to use my brand new holders...

I got 4 nikken sk10 collet chucks and a couple centaur ER16's that are the wrong type (looks like MAS BT35 vs regular BT35) These are brand new...

What gives here?? I guess there are machines out there that use this other spec of BT35?

Anyone know a source for ER chucks with the old BT35 to fit my kitamura? I am not even sure how to tell which one I am looking at online, as no one seems to differentiate the two specs, but so far 100% of what I have bought new has been wrong....

See here http://www.lyndexnikken.com/cp/303A/E189.pdf

Thanks

Vegard