Ox

Diamond

- Joined

- Aug 27, 2002

- Location

- Northwest Ohio

I know that Siemens doesn't have much support here on this site, but thought that I'd toss this out to see if I get lucky:

I have a call into Siemens, but the voice there was not very knowledgeable. He was reading through a manual, but was going to hafta check with others and git back to me, likely Monday morning.

I have a PCU50 (2002) Pentium 2, 333mhz (pendant? Memory storage unit?) and a 1P_6FC5447_0AA00_0AA1 control down in the cabinet with an 8MGB memory card.

The CRT seems to show that the hard drive has more memory available than Carter had them little liver pills, but it seems that the "CNC" unit down below aint got squat capacity. Yet it has an 8M card in it?

Siemens should be getting back to me with their version of what it would take to get to 1.5M ability on the CNC unit. ($?)

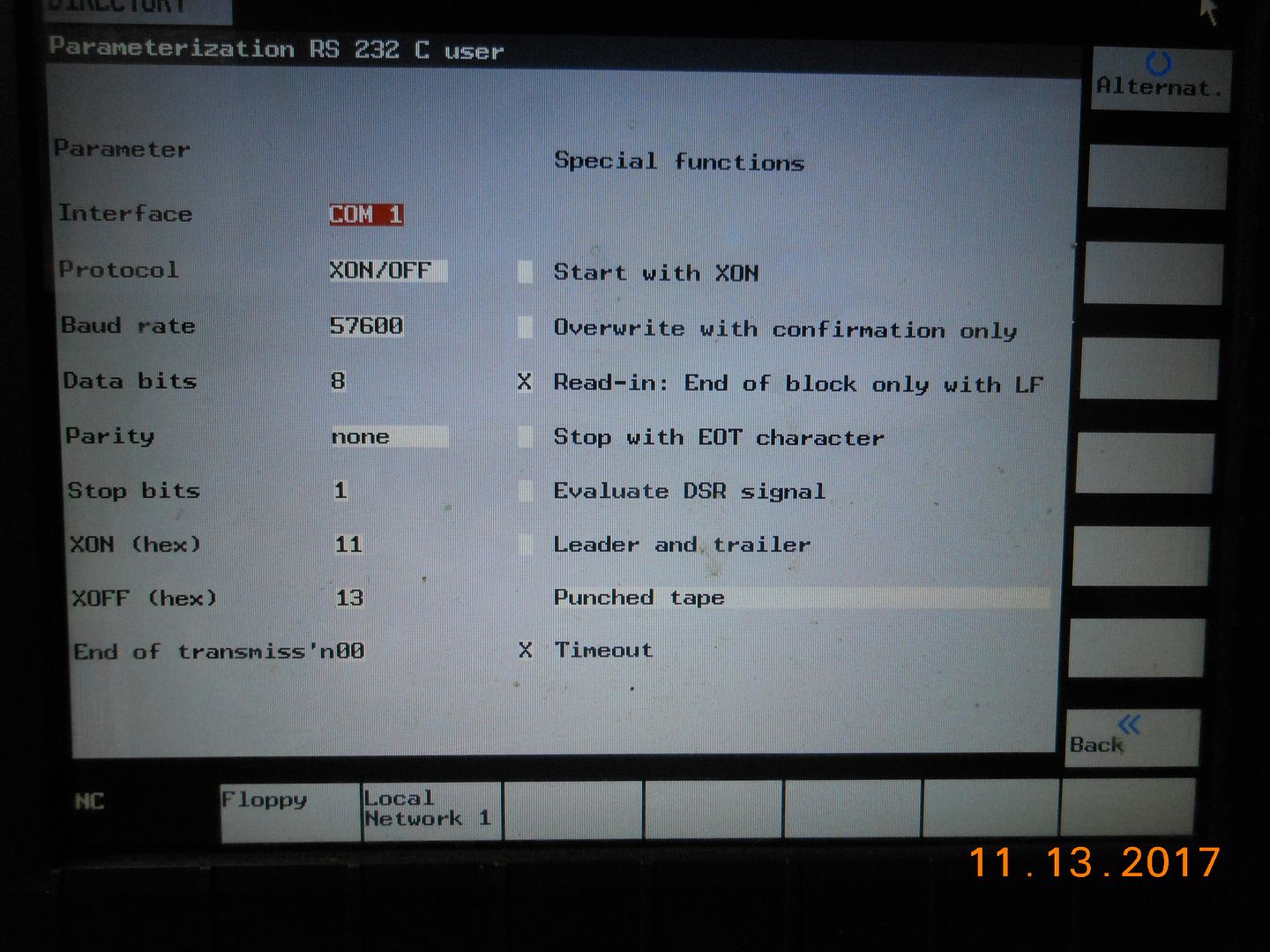

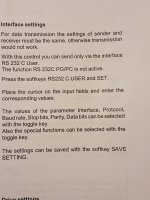

Also, wondering about the ability to maybe drip feed it? The voice at Siemens wasn't sure about that either.

Anyone here have any experience to share on the subject?

-------------------

Think Snow Eh!

Ox

I have a call into Siemens, but the voice there was not very knowledgeable. He was reading through a manual, but was going to hafta check with others and git back to me, likely Monday morning.

I have a PCU50 (2002) Pentium 2, 333mhz (pendant? Memory storage unit?) and a 1P_6FC5447_0AA00_0AA1 control down in the cabinet with an 8MGB memory card.

The CRT seems to show that the hard drive has more memory available than Carter had them little liver pills, but it seems that the "CNC" unit down below aint got squat capacity. Yet it has an 8M card in it?

Siemens should be getting back to me with their version of what it would take to get to 1.5M ability on the CNC unit. ($?)

Also, wondering about the ability to maybe drip feed it? The voice at Siemens wasn't sure about that either.

Anyone here have any experience to share on the subject?

-------------------

Think Snow Eh!

Ox