Terrible Juan

Cast Iron

- Joined

- Dec 22, 2009

- Location

- South Central Mountain USA

Hi guys,

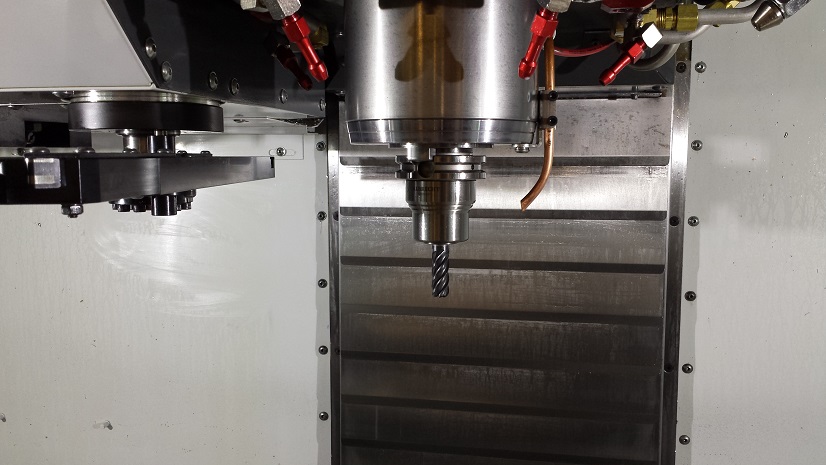

I'm helping a customer find a solution for air blast on their vertical mill. The machine currently has an air blast option and uses Line Loc connectors to spray the air. It is not my favorite setup because we really need to get the air blast close to the tool tip. If we adjust the air line too close, it won't be able to do a tool change without manually moving the nozzle away. For what we are machining, it is very necessary to get the air nozzle as close to the tip as possible.

I know that HAAS verticals come with a really cool air blast nozzle that retracts in and out when in use or not in use. Anyone ever piece together something like that to a machine that isn't a HAAS?

You can see it in action here:

https://youtu.be/3hkV9J1Mrxo?t=2m15s

I'm helping a customer find a solution for air blast on their vertical mill. The machine currently has an air blast option and uses Line Loc connectors to spray the air. It is not my favorite setup because we really need to get the air blast close to the tool tip. If we adjust the air line too close, it won't be able to do a tool change without manually moving the nozzle away. For what we are machining, it is very necessary to get the air nozzle as close to the tip as possible.

I know that HAAS verticals come with a really cool air blast nozzle that retracts in and out when in use or not in use. Anyone ever piece together something like that to a machine that isn't a HAAS?

You can see it in action here:

https://youtu.be/3hkV9J1Mrxo?t=2m15s

)

)