The 3 opinions that you got were pretty damn good if you ask me.

At least you could address those before bitching that you didn't get a 50 page thread.

Not a lot to say.. Essentially the same machine from the 80's up into the 2000's..

Parts are cheap and available from many sources.

Options are all hardware only, there are no software options, the control can do it all.

The control is simple and menu driven, with some fantastic tool and fixture setting utilites.

Parameters are 3 simple pages written in english, even if you lose them, takes 2 minutes to re-enter them.

15hp is a REAL 15hp continuous, 22.5 for 5 minutes or something.. 2 speed head, so a ton of F'n torque.

The down sides..

Its not a Mazak, Its not a Mori.

Its not the fastest thing going.

Toolchanges will literally put you to sleep.

Its a simple commodity machine that does need to be maintained.

Lot of bang for the buck, and there is a metric buttload of them still making chips

so parts should be available for a very long time.

I also feel they are getting towards the bottom on pricing, so its not a bad time to buy.

Not conversational, though I believe from 95 and up there is a weak attempt at some form of

conversational that I don't think anybody has ever used.

As for your blown boards, ITS can probably fix 'em up for ya.. Also, I'm a firm believer in

buying 2 machine (looks like you are leaning that way).. Its really nice being able to compare

machine to machine and being able to swap boards from machine to machine, that can save you a

ton of time and money if you are trouble shooting a problem... Also, less spare parts to keep

on hand, I keep a set of bellevilles, a floater (DO NOT FORGET THE FLOATER!!), a few sets of

thrust bearings and a spare set of belts on hand.

They are great machines, though not the fastest, if you MAINTAIN them... You HAVE TO MAINTAIN them...

If you maintain them, they can be damn accurate and rigid enough to use every bit of HP they have.

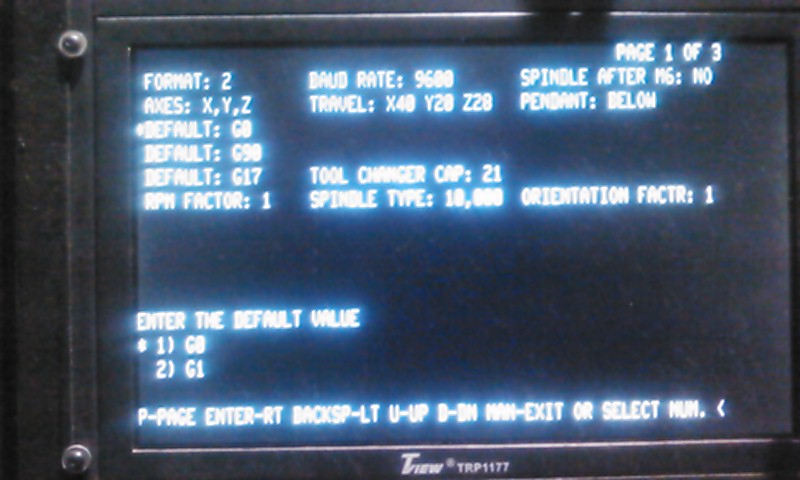

Pic of one of the 3 parameter pages.. See how EASY that is.. No page after page after page

of hexadecimal and binary bullshit, just plain simple english.

This machine came to me with .019" of slop in the Y, and only about 12 of the 40 something

bellevilles in tact. She was in rough shape.. Now she can interpolate a hole within a thou,

no witness marks and I've pulled 23 cubic inches a minute in mild steel with a half inch endmill.

This phote (I've posted it many times), just shy of 3 of these piles of annealed 4340 on a

single half inch endmill pulling somewhere around 12 cubic inches a minute.

You have to maintain them says the guy with 600lbs of metal chips holding up the travel of the X axis and a can of Bud Light on the chips.

You have to maintain them says the guy with 600lbs of metal chips holding up the travel of the X axis and a can of Bud Light on the chips.