MazatrolMatrix

Aluminum

- Joined

- Sep 27, 2015

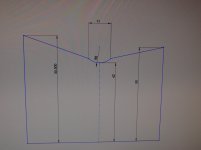

So I got this part I'm supposed to make, but the drawing is missing some information, Which I don't know how to calculate. Maybe you guys can help me out, if it's even possible..

I need to know the starting point of the Z axis for the 8 mm radius, and since the radius centre isn't in between the 11 measurement, I'm kind of lost. If possible I'd also like to learn how it's done Thanks for the help! Oh, and the measurements of my sketch isn't correct, it's just a sketch of the principle of the problem

Thanks for the help! Oh, and the measurements of my sketch isn't correct, it's just a sketch of the principle of the problem

I need to know the starting point of the Z axis for the 8 mm radius, and since the radius centre isn't in between the 11 measurement, I'm kind of lost. If possible I'd also like to learn how it's done

Thanks for the help! Oh, and the measurements of my sketch isn't correct, it's just a sketch of the principle of the problem

Thanks for the help! Oh, and the measurements of my sketch isn't correct, it's just a sketch of the principle of the problem