Ox

Diamond

- Joined

- Aug 27, 2002

- Location

- Northwest Ohio

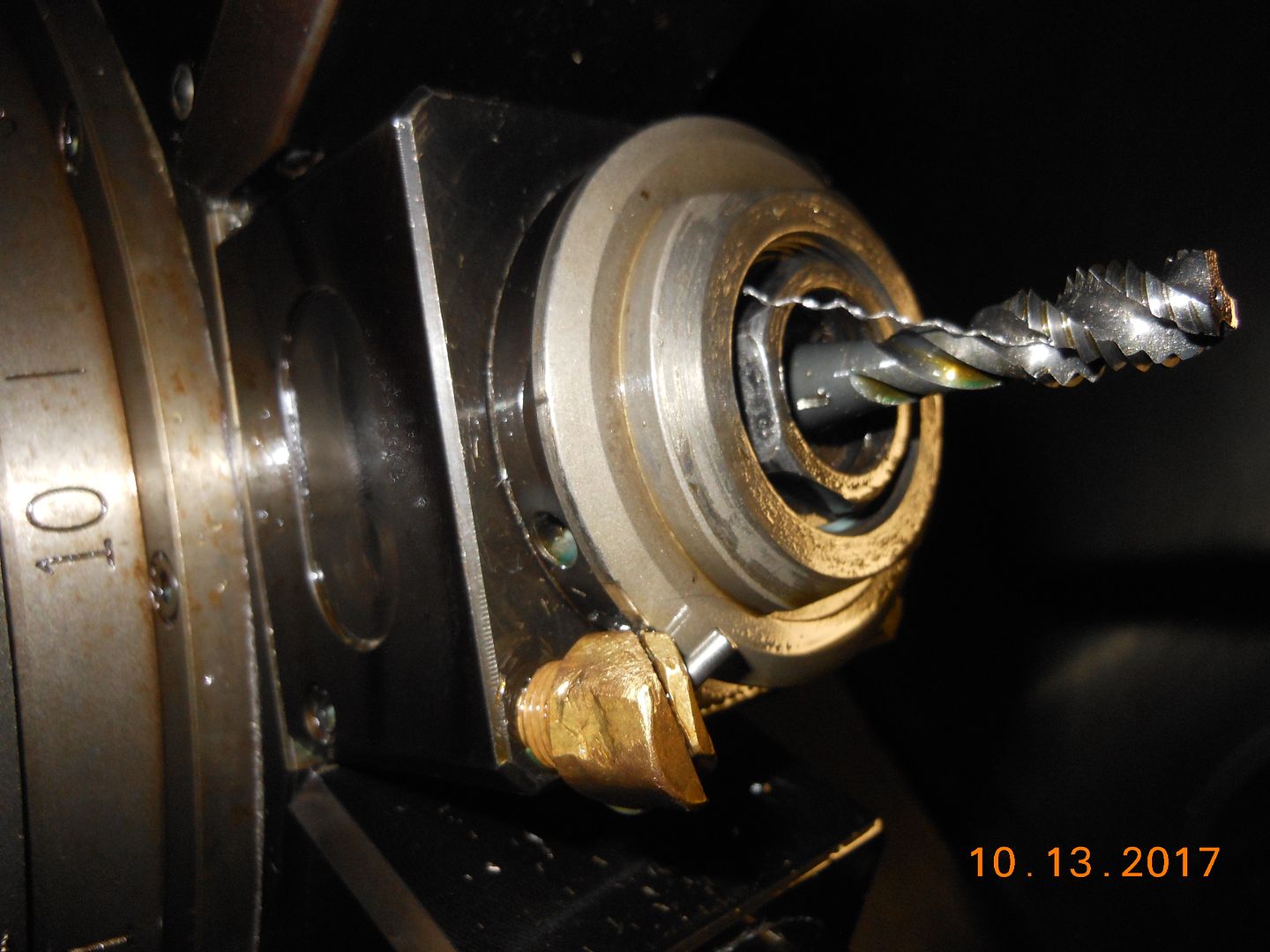

I seldom ever use an actual tap collet, but have an app that we are right now, but the collet nut is absolutely buried! (internal for live toy lathe)

With an outside milling chuck - we would prolly hardly notice it, but in the lathe - it's an issue.

Just wondering if they are all this way, or if someone makes them that would be more at the top or mid of the [external] size range?

--------------------

Think Snow Eh!

Ox

With an outside milling chuck - we would prolly hardly notice it, but in the lathe - it's an issue.

Just wondering if they are all this way, or if someone makes them that would be more at the top or mid of the [external] size range?

--------------------

Think Snow Eh!

Ox