Stephan Spears

Aluminum

- Joined

- Apr 12, 2014

- Location

- AB,Canada

Has anyone taken a closer look at the output of G31??

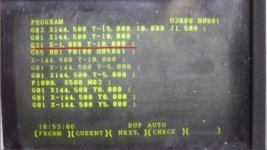

In a scenario where a probe is on the machine which is currently at the position X150 Y0 Z0. Consider the following NC program,

N1 G31 X200. F1000;

N2 #1=#5061;

N3 #2=#5041;

N4 M0;

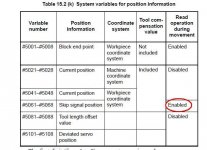

During the motion of G31, if the SKIP signal is turned on high when the machine reaches X180 physically, the machine will capture system variables #5061, #5041 and save them to #1 and #2.

When the CNC recognize the skip signal, the machine is at 180.003.

When the machine motion stops, the machine is at 182.5.

what are the outcomes of #1 and #2?

Are they

#1 = 180.003 (Current machine position when the CNC recognize the skip signal)

#2 = 182.5 (Machine position when the machine motion stops)

or

#1 = 182.5 (Machine position when the machine motion stops)

#2 = 182.5 (Machine position when the machine motion stops)

??

Thanks in advance.

Steph

In a scenario where a probe is on the machine which is currently at the position X150 Y0 Z0. Consider the following NC program,

N1 G31 X200. F1000;

N2 #1=#5061;

N3 #2=#5041;

N4 M0;

During the motion of G31, if the SKIP signal is turned on high when the machine reaches X180 physically, the machine will capture system variables #5061, #5041 and save them to #1 and #2.

When the CNC recognize the skip signal, the machine is at 180.003.

When the machine motion stops, the machine is at 182.5.

what are the outcomes of #1 and #2?

Are they

#1 = 180.003 (Current machine position when the CNC recognize the skip signal)

#2 = 182.5 (Machine position when the machine motion stops)

or

#1 = 182.5 (Machine position when the machine motion stops)

#2 = 182.5 (Machine position when the machine motion stops)

??

Thanks in advance.

Steph