Abrasive Machine

Plastic

- Joined

- Feb 5, 2016

Hello guys,

I wanted to ask suggestions/ideas for manufacturing of shafts,

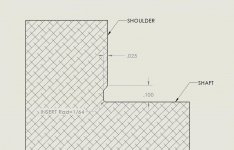

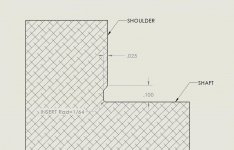

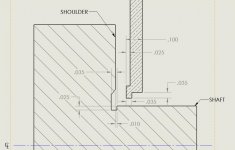

typically when we make aluminum shafts and we have to put an undercut for when we grind the shaft and the shoulder, the company has used the 45 Degree 0.060 wide undercut shown on the "Orig" image

My boss wants to make new undercuts that are small on other tooling that we want to make out of steel(a2)

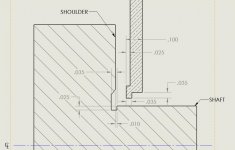

so I drew a drawing that shows the "roughed" shaft and shoulder with an initial undercut.

then tool number 2 comes in and creates the undercut as shown on picture "relief 2"

Question is, is there tooling that can do that(or something similar to that)? or do we need to make our own tooling for this?

my dimensions on the drawings are just as reference so any recommendations if they are do-able or forget about doing something like this?

Any help appreciated.

Thanks

I wanted to ask suggestions/ideas for manufacturing of shafts,

typically when we make aluminum shafts and we have to put an undercut for when we grind the shaft and the shoulder, the company has used the 45 Degree 0.060 wide undercut shown on the "Orig" image

My boss wants to make new undercuts that are small on other tooling that we want to make out of steel(a2)

so I drew a drawing that shows the "roughed" shaft and shoulder with an initial undercut.

then tool number 2 comes in and creates the undercut as shown on picture "relief 2"

Question is, is there tooling that can do that(or something similar to that)? or do we need to make our own tooling for this?

my dimensions on the drawings are just as reference so any recommendations if they are do-able or forget about doing something like this?

Any help appreciated.

Thanks