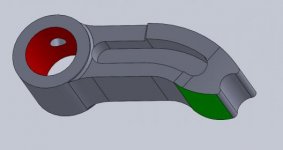

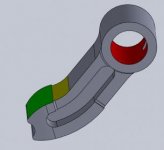

Hi all, I'm looking to get someone here on this forum (preferably in USA) to machine 20 or 36 pieces (quantity will be determined by price) of the attached part out of S7 tool steel and it seems that there's no RFQ section here. After machining I plan to get the sliding surfaces ground/honed then DLC coated. I don't have any experience with getting jobs precision ground so what I need to know is can the small radius (green) on the underside be ground due to how that surface comes back and meets the main body at the yellow surface which is an R8mm and if so how? They manage it okay on OEM products but they've got millions to spend on specialist tooling. The way it is at present would either need a 16mm grinding wheel OR it gets ground in the other direction with the flat of the wheel against the surface OR should I redesign the part. I purposely didn't include any chamfers or filleting in the drawing at this stage. Thanks in advance for your advice.

View attachment 214856View attachment 214855View attachment 214857View attachment 214858

View attachment 214856View attachment 214855View attachment 214857View attachment 214858

Attachments

Last edited: