PaulT

Stainless

- Joined

- Mar 4, 2002

- Location

- Brisbane, CA, USA

We're working on a new product that starts as a long block of 6" x 1" 6061 aluminum.

The top of this block needs to be highly polished, after some pockets have been machined in it.

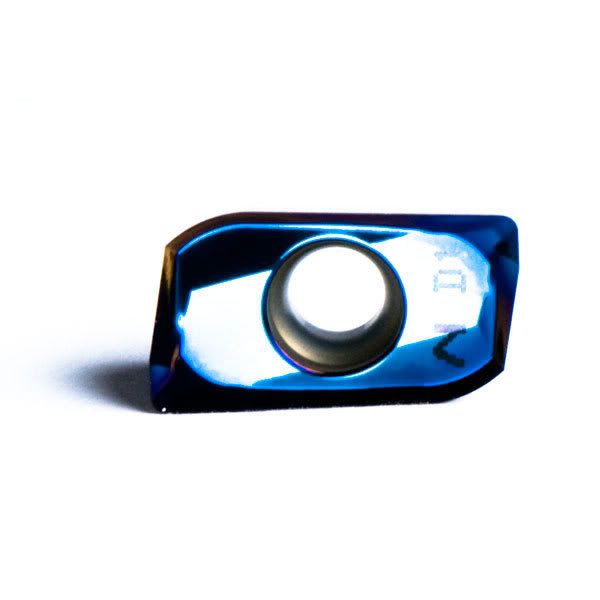

On the prototype, with the tooling we currently have we're using a 3" diameter APKT insert based face mill to make a 0.012" skim cut on the block, but with about 70% overlap it takes 3 passes and we're seeing some transition lines on the part, along with some fine machining lines.

We then go through a power sanding and then buffer wheel polishing procedure to get a pretty nice close to mirror finish, and this has been fine for the prototypes.

But I need to speed the process up for the real products. To reduce the amount of sanding and polishing required, I need to improve the finish quality of the facing skim cut we're taking.

Starting from scratch, what would be the best facing mill design and insert type to get the best possible finish on the facing cut we're taking?

Its ok if its a very slow pass, it will still pay off in reducing the sanding/polishing step.

Looking around a little it appears that a one or two insert based "fly cutting" type tool might be the best approach, is that true? (and if its that simple, I might just fabricate the tool)

I've never used and don't know anything about "wiper" inserts, would a wiper insert help?

Thanks,

Paul T.

The top of this block needs to be highly polished, after some pockets have been machined in it.

On the prototype, with the tooling we currently have we're using a 3" diameter APKT insert based face mill to make a 0.012" skim cut on the block, but with about 70% overlap it takes 3 passes and we're seeing some transition lines on the part, along with some fine machining lines.

We then go through a power sanding and then buffer wheel polishing procedure to get a pretty nice close to mirror finish, and this has been fine for the prototypes.

But I need to speed the process up for the real products. To reduce the amount of sanding and polishing required, I need to improve the finish quality of the facing skim cut we're taking.

Starting from scratch, what would be the best facing mill design and insert type to get the best possible finish on the facing cut we're taking?

Its ok if its a very slow pass, it will still pay off in reducing the sanding/polishing step.

Looking around a little it appears that a one or two insert based "fly cutting" type tool might be the best approach, is that true? (and if its that simple, I might just fabricate the tool)

I've never used and don't know anything about "wiper" inserts, would a wiper insert help?

Thanks,

Paul T.