How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to machine this part?

- Thread starter sinha

- Start date

- Replies 8

- Views 5,093

jCandlish

Titanium

- Joined

- Jun 1, 2011

- Location

- Oberaargau, Swizerland

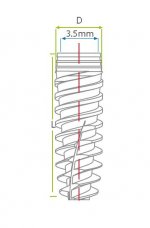

I was wondering how this screw-like part was machined.

The helix is same, and the thickness of the tooth gradually changes.

On this Tornos demo the helix is thread whirled.

tay2daizzo8

Hot Rolled

- Joined

- Nov 8, 2013

- Location

- north of Bean town

Very carefully lol... if the pitch of helix is the same then its just the groove width changing, a 2 axis cnc should do it I would think or swiss?

bukwerm

Cast Iron

- Joined

- Nov 6, 2013

- Location

- Minneapolis MN

It looks to me like the minor diameter simply has more taper than the major diameter.

PixMan

Diamond

- Joined

- Jan 30, 2007

- Location

- Central MA USA

I've done thread whirling on titanium bone screws on CNC Swiss machines, that dental implant is no different. The key feature note is that the O.D. shape is turned first, and then the thread shape is milled (whirled) to it's own root profile. The width of the thread root is constant as it's ground into the inserts in the whirling head. The depth of the thread changes and that's why the width of the crests change. I've seen (and made) increasing tighter helix to keep thread crest equal, though I can't understand how it screws in without blowing apart the bone.

SIM

Titanium

- Joined

- Feb 19, 2004

- Location

- Staten Island NewYork USA

I I've seen (and made) increasing tighter helix to keep thread crest equal, though I can't understand how it screws in without blowing apart the bone.

I guess that is why we machinists machine and doctors do whatever it is they do besides play golf and take too much of my money.

lanb

Aluminum

- Joined

- Jun 29, 2006

- Location

- Colo Spgs CO

So what is thread whirling?

From the above video is looks like the tool would be like an way oversized threading die with teeth similar in form to a thread mill but on the inside which is then spun and moved around the part along a helical path.

Am I close? and if so what is the advantage over a thread mill?

Thanks,

Lan

From the above video is looks like the tool would be like an way oversized threading die with teeth similar in form to a thread mill but on the inside which is then spun and moved around the part along a helical path.

Am I close? and if so what is the advantage over a thread mill?

Thanks,

Lan

Dcrouch

Cast Iron

- Joined

- Jul 23, 2004

- Location

- Pocomoke, MD

I've got dental implants and when it comes to screwing them in Dentists are NOT machinists. When he was drilling for the implants all I could think of is what the hell is he going to do when he breaks the drill off! This is freehanded with the drill in a dentists drill. Then torque the implant in. I could just imagine my jaw bone cracking open as he screwed them in.

implmex

Diamond

- Joined

- Jun 23, 2002

- Location

- Vancouver BC Canada

Hi All:

This is a subject dear to my heart as I've been on both sides; I was a dentist once upon a time and did implant surgeries as part of my practice, and I'm now a maker and designer of dental implants and instruments among other things.

With regard to variable pitch screws on dental implants; sometimes there's supposedly a reason to make such a beast, but mostly it's just marketing bullshit.

I've done plenty of designs and consulted with a number of implant companies over the past 15 years and I've seen precious little bio engineering or biological science in many of the designs, but I've seen lots of "Me Too" designs and a few "And Now For Something Completely Different" designs all of which have promptly faded into oblivion only to be resurrected years later by the new marketing team in a different corner of the world and touted yet again as groundbreaking revelation.

So your intuition is spot-on, PixMan; they CANNOT work in any revolutionary way other than as a marketing gimmick, and they certainly don't improve the outcome of the surgery.

On the subject of thread whirling; the principal advantage of the whirler is that threads of long length can be cut because the finished thread passes through the hollow center of the cutter, unrestricted by a cutter shank or a collet.

Another advantage is that the whirler is easily canted to the helix angle of the thread, so the thread profile is undistorted; in contrast to a threadmill in a VMC where the profile of the thread flanks gets more and more distorted as the pitch of the thread increases and the diameter of the thread decreases.

With regard to making these odd thread forms, a key to understanding them is to look at the shape of a single gullet at the root of the thread, and the angles of the flanks as PixMan points out; if those are unchanging over the length of the thread then whatever variability exists in the remainder of the profile has been accomplished by changing either the crest profile, the pitch, the root profile or the thread depth or any combination of the above.

These things are relatively easy to do, so those threads are not as bad to make as they look.

The really nasty ones to cut are those where the profile of the gullet changes as the thread traverses the length of the part.

Here's a picture of such a thread; it was cut in multiple passes with a tool that traversed from the trailing flank to the leading flank in successive little nibbles.

It took lots of code to make this part; in production these will also be whirled rather than single point threaded as I did with these prototypes, but the nibbling of the variable gullet profile will have to be accomplished with the same traverses of the tool from trailing flank to leading flank in bitty bites.

With regard to driving the dental implants into people's jaws; the bone has a tough outer shell called the cortex and a lattice like center called the medulla.

It comes in varying hardness, toughness and thickness depending on a bunch of physiological factors and on the particular place in the mouth where the implant is placed.

When the dentist drills the hole (or "creates the osteotomy" in dentist lingo) he or she is supposed to judge what density and thickness the cortical layer is, in order to judge whether to pre-tap the hole or countersink the edge of the hole with a tapered reamer in order to get the implant in without killing the bone by putting too much pressure on it or fracturing the jaw by wedging an implant into too small a hole in excessively dense bone.

It's a bit of a judgement call but it's really not rocket science; any competent woodworker, used to driving screws into his woodworking projects knows exactly what it should feel like, and this is no different.

A good surgeon rarely has a misadventure, and when they do it's usually because of weird anatomical variation, or unrevealed pathology, not because he or she was ham fisted.

Cheers

Marcus

Implant Mechanix – Design & Innovation - home

Vancouver Wire EDM -- Wire EDM Machining

This is a subject dear to my heart as I've been on both sides; I was a dentist once upon a time and did implant surgeries as part of my practice, and I'm now a maker and designer of dental implants and instruments among other things.

With regard to variable pitch screws on dental implants; sometimes there's supposedly a reason to make such a beast, but mostly it's just marketing bullshit.

I've done plenty of designs and consulted with a number of implant companies over the past 15 years and I've seen precious little bio engineering or biological science in many of the designs, but I've seen lots of "Me Too" designs and a few "And Now For Something Completely Different" designs all of which have promptly faded into oblivion only to be resurrected years later by the new marketing team in a different corner of the world and touted yet again as groundbreaking revelation.

So your intuition is spot-on, PixMan; they CANNOT work in any revolutionary way other than as a marketing gimmick, and they certainly don't improve the outcome of the surgery.

On the subject of thread whirling; the principal advantage of the whirler is that threads of long length can be cut because the finished thread passes through the hollow center of the cutter, unrestricted by a cutter shank or a collet.

Another advantage is that the whirler is easily canted to the helix angle of the thread, so the thread profile is undistorted; in contrast to a threadmill in a VMC where the profile of the thread flanks gets more and more distorted as the pitch of the thread increases and the diameter of the thread decreases.

With regard to making these odd thread forms, a key to understanding them is to look at the shape of a single gullet at the root of the thread, and the angles of the flanks as PixMan points out; if those are unchanging over the length of the thread then whatever variability exists in the remainder of the profile has been accomplished by changing either the crest profile, the pitch, the root profile or the thread depth or any combination of the above.

These things are relatively easy to do, so those threads are not as bad to make as they look.

The really nasty ones to cut are those where the profile of the gullet changes as the thread traverses the length of the part.

Here's a picture of such a thread; it was cut in multiple passes with a tool that traversed from the trailing flank to the leading flank in successive little nibbles.

It took lots of code to make this part; in production these will also be whirled rather than single point threaded as I did with these prototypes, but the nibbling of the variable gullet profile will have to be accomplished with the same traverses of the tool from trailing flank to leading flank in bitty bites.

With regard to driving the dental implants into people's jaws; the bone has a tough outer shell called the cortex and a lattice like center called the medulla.

It comes in varying hardness, toughness and thickness depending on a bunch of physiological factors and on the particular place in the mouth where the implant is placed.

When the dentist drills the hole (or "creates the osteotomy" in dentist lingo) he or she is supposed to judge what density and thickness the cortical layer is, in order to judge whether to pre-tap the hole or countersink the edge of the hole with a tapered reamer in order to get the implant in without killing the bone by putting too much pressure on it or fracturing the jaw by wedging an implant into too small a hole in excessively dense bone.

It's a bit of a judgement call but it's really not rocket science; any competent woodworker, used to driving screws into his woodworking projects knows exactly what it should feel like, and this is no different.

A good surgeon rarely has a misadventure, and when they do it's usually because of weird anatomical variation, or unrevealed pathology, not because he or she was ham fisted.

Cheers

Marcus

Implant Mechanix – Design & Innovation - home

Vancouver Wire EDM -- Wire EDM Machining

Attachments

Similar threads

- Replies

- 25

- Views

- 1K

- Replies

- 9

- Views

- 738