SDConcepts

Stainless

- Joined

- Mar 1, 2007

- Location

- warren, mi

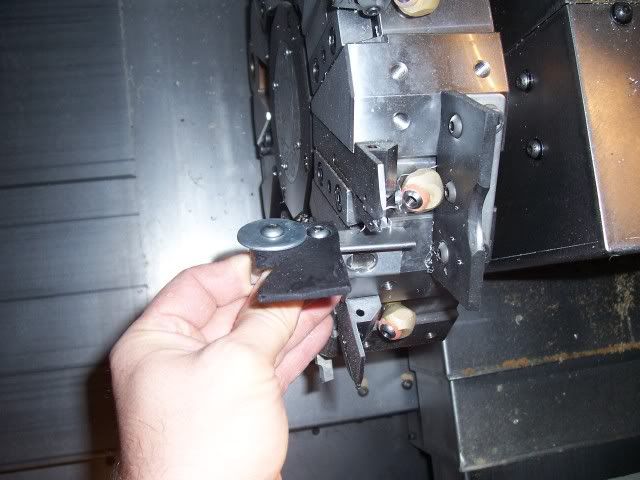

i've got a job where i'm running 5 parts simultaneously. the parts are fairly small and so far i catch about2 out of parts parts repeatably. the first one i lose all the time since its at the end. the second one i usually lose. i usually catch 3 and 4 and then 5 is usually lost as well. basically the catcher is wide enough to span the length of all the parts but they are being flung after cut off. i've tried slowing it down and it doesn't help and speeding up only makes it worse.