Gearheaded

Plastic

- Joined

- Jun 21, 2010

- Location

- Portland, Oregon, USA

Hi Everyone:

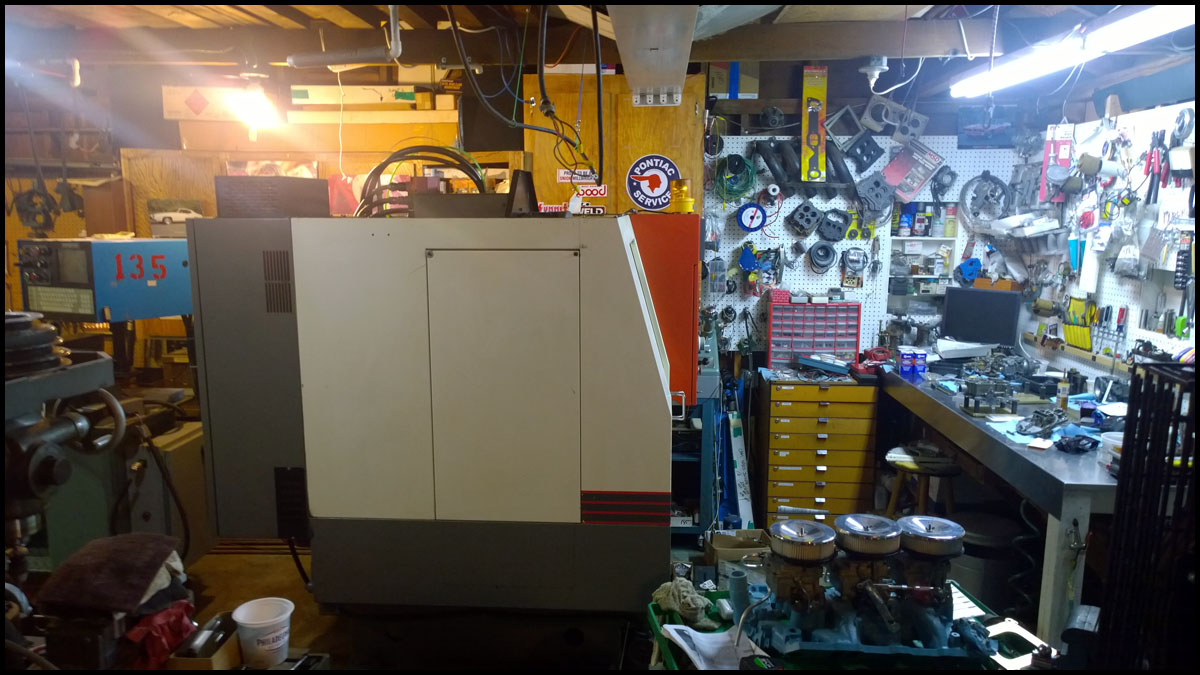

I don't post much, I think only about 7 times or so over the years. Mostly a lurker with little time and only like to post if I'm adding something to the conversation. I've learned a great deal from reading here over the years. My first "real" cnc mill has finally arrived at it's new home, despite some interesting challenges over the last few months, and I would like to post a couple pictures and ask just a couple questions and see if anyone knows much about the machine I purchased.

A little background...I've got a nice little machine shop that I've been building up for 20 years a little at a time. I rarely do job shop type work at home, and own the shop mainly for production of my own products with a few production jobs from various friends now and then. Its basically my retirement plan, since I don't have any other. But all machines paid for...very low overhead, and no debt.

I've gathered up machines on the cheap when I could find and afford them, but have never been able to complete the loop with a "real" cnc mill until now.

My machine list as of now in order of purchass:

1995-Sherline manual lathe...I know, a silly hobby toy but it was a start, and I still use it regularly for small quick carburetor parts and such.

1996-Hardinge DSMA automatic turret lathe with bar feeder...paid for itself many times over

1997 Sherline CNC mill with tooling bought new...Taught myself milling and G code and even made some money with it

1998 Enco 12 x 38 manual lathe...nearly new

1999 Mid size manual mill from the now defunct Tektronics tooling shop

2002 Small injection molding machine

2003 Elgin manual turret lathe for second ops

2004 Burris 6 position turret drill press...traded carburetor rebuild for it

2005 1967 Tornos cam style swiss screw machine...awesome machine, every attachment, also from Tek making oscilloscope parts. Sold this one last year to make room

summer 2005 went to North Carolina for awhile to run a big machine shop in Charlotte making parts for Freightliner...No machine puchases for awhile

2008 Omniturn Hardinge CNC lathe

2011 My second Omniturn Hardinge

2012 Sunnen honing machine with large selection of mandrels and stones

2014 DynaMyte CNC 2400...Free to me, brand new from a school that never used it. 1980's desktop CNC mill

2016 Feeler surface grinder

and finally

2017-18 My new to me Kira/Tree CNC mill

Last year in the spring I spied this mill on craigslist. It was in the high desert of central Oregon for I think $7500. Looked cool but I didn't have the money then and wasn't in machine buying mode anyway. Fast forward to September...I happen to check out craigslist, and the machine is still there, price unchanged. I had a little money(didn't really want to spend it) but my interest and curiosity were starting to get the better of me. I called him in early October and talked to him about the machine. He felt it was a great machine he had bought for himself, but quickly realized he needed larger and bought a large older Fadal.

Having just had my 54th birthday, I convinced my significant other that we needed to at least go to check it out, it would make a nice trip to central Oregon, and we could stop and check out trains and railroad bridges...she loves trains and railroad bridges.

We got to the shop and it was the cutest little machine. Measured and would barely fit through my garage door...but it would fit! I got the story on the machine and where it came from. Told him I would need to do some research before making an offer. So I went online and searched this forum and general search and found enough info to convince me I should be interested. Made an appointment to visit again in late October. Brought my indicators and volt meter and gave it a thorough checkout. All seemed good, and I liked the guy, we had similar backgrounds and I felt I could trust what he had to say. He said he had about 30 BT30 tool holders that he wanted to sell separate. I asked what the lowest price to get the machine and tooling out of his life. He said $5500 and I said yes.

Now came the problems. I didn't have room for the machine and little time from working two jobs. I had to solve at least one of the problems right away...so I quit my primary job as a machinist of plastics making $25/hr plus bennies. That felt really good...no more getting up at 6am. Of course no more biweekly decent paychecks either.

I moved the manual turret lathe and honing machine into my storage container and was surprised to find I might have room after all.

So we made arrangements for my friend to pick up the machine and store it for awhile so I could get the garage ready. We were leaving on our first vacation in years for a week in Tahoe and then to the Bay area(Santa Cruz) to visit family. He was to follow me on the morning we were leaving, going the back way to Tahoe so we could stop at Central Oregon. Truck broke down on they way. Guy with machine was cool about it and we would handle it after returning.

While we were gone, we decided to get married so now I have a wife.

Upon returning, our boss from my part time job(my wife is a welder fabricator and works with me at the other job)decided to have us be full time, between the two of us, about three times the money from the job shop, but now back to super busy. Now the guy is starting to call wondering when the machine will leave and the rest of the money arrive, so I make arrangements right before Xmas to try again, this time the turbo blows on the way over the mountains. Ughhh.

So I let my friend off the hook, and call a different friend, but this one can't store it, so I have to bring it home. Also, when I told the machine owner we were on the road, he moved the machine outside so we could load it easier....needless to say, now the machine is outside in the winter under a tarp. Ughhh again...and a big storm is coming that will make it over the cascades. Ughhh some more.

I didn't have a choice but to wait out the storm and let the roads clear of snow, but we finally went and got it last week, and it went without a hitch other than not enough forklift, so I had to bring my millwright skills out of mothballs and figure out how to get it on the trailer. It wasn't fun but we succeeded with a block and tackle, lubricant, winches and come alongs.

Bringing it home we had a larger forklift available but only two inches clearance to the garage door. It took some fiddling with forlift forks and pallet jack, but we got it into the garage in a nice spot for me to work.

The machine is a 1991 Kira/Tree CNC mill with 10 tool positions. 5hp spindle, 787"/min rapids, 350"/min milling. Rigid Tapping, chip auger, Fanuc OM Mate control. It is more than fast enough for the work I do, and looks to be well designed and built.

The machine came with 86 tool holders of which 80% of them look to be in perfect shape, and the rest in reasonable shape.

I was able to buy a like new 20hp RPC from a friend for $1000 to get it running.

There are a couple of questions I have about it though, and am hoping someone here can enlighten me.

Here are some pictures, I will ask the questions at the bottom of the post.

I have three questions:

First: In the book it shows 12000rpm spindle, then refers to torque curves for three speed ranges. 0-4000, 0-8000, and 0-12000rpm. there does not seem to be any indication that these were options for the spindle, so...does that mean they simply have different control settings to create different speed and torque ratings for the spindle? Or do I misunderstand and there are three separate spindle options?

Second: The mill table is in wonderful shape and looks to have never been crashed into...however, it is a cross slot with eight mounting holes for fixture plates. The machine came with a nice fixture plate with dowel pins. Is there a company that makes reasonably priced custom T slot tables that could be bolted to the mill table?

Third: Anybody run or own one of these and have any possible tips or hints about running this machine?

Thank you all for your time and the many years of great and valuable info I have gleaned from Practical Machinist. And sorry bout the long post and diatribe.

Karl

Portland, Oregon

I don't post much, I think only about 7 times or so over the years. Mostly a lurker with little time and only like to post if I'm adding something to the conversation. I've learned a great deal from reading here over the years. My first "real" cnc mill has finally arrived at it's new home, despite some interesting challenges over the last few months, and I would like to post a couple pictures and ask just a couple questions and see if anyone knows much about the machine I purchased.

A little background...I've got a nice little machine shop that I've been building up for 20 years a little at a time. I rarely do job shop type work at home, and own the shop mainly for production of my own products with a few production jobs from various friends now and then. Its basically my retirement plan, since I don't have any other. But all machines paid for...very low overhead, and no debt.

I've gathered up machines on the cheap when I could find and afford them, but have never been able to complete the loop with a "real" cnc mill until now.

My machine list as of now in order of purchass:

1995-Sherline manual lathe...I know, a silly hobby toy but it was a start, and I still use it regularly for small quick carburetor parts and such.

1996-Hardinge DSMA automatic turret lathe with bar feeder...paid for itself many times over

1997 Sherline CNC mill with tooling bought new...Taught myself milling and G code and even made some money with it

1998 Enco 12 x 38 manual lathe...nearly new

1999 Mid size manual mill from the now defunct Tektronics tooling shop

2002 Small injection molding machine

2003 Elgin manual turret lathe for second ops

2004 Burris 6 position turret drill press...traded carburetor rebuild for it

2005 1967 Tornos cam style swiss screw machine...awesome machine, every attachment, also from Tek making oscilloscope parts. Sold this one last year to make room

summer 2005 went to North Carolina for awhile to run a big machine shop in Charlotte making parts for Freightliner...No machine puchases for awhile

2008 Omniturn Hardinge CNC lathe

2011 My second Omniturn Hardinge

2012 Sunnen honing machine with large selection of mandrels and stones

2014 DynaMyte CNC 2400...Free to me, brand new from a school that never used it. 1980's desktop CNC mill

2016 Feeler surface grinder

and finally

2017-18 My new to me Kira/Tree CNC mill

Last year in the spring I spied this mill on craigslist. It was in the high desert of central Oregon for I think $7500. Looked cool but I didn't have the money then and wasn't in machine buying mode anyway. Fast forward to September...I happen to check out craigslist, and the machine is still there, price unchanged. I had a little money(didn't really want to spend it) but my interest and curiosity were starting to get the better of me. I called him in early October and talked to him about the machine. He felt it was a great machine he had bought for himself, but quickly realized he needed larger and bought a large older Fadal.

Having just had my 54th birthday, I convinced my significant other that we needed to at least go to check it out, it would make a nice trip to central Oregon, and we could stop and check out trains and railroad bridges...she loves trains and railroad bridges.

We got to the shop and it was the cutest little machine. Measured and would barely fit through my garage door...but it would fit! I got the story on the machine and where it came from. Told him I would need to do some research before making an offer. So I went online and searched this forum and general search and found enough info to convince me I should be interested. Made an appointment to visit again in late October. Brought my indicators and volt meter and gave it a thorough checkout. All seemed good, and I liked the guy, we had similar backgrounds and I felt I could trust what he had to say. He said he had about 30 BT30 tool holders that he wanted to sell separate. I asked what the lowest price to get the machine and tooling out of his life. He said $5500 and I said yes.

Now came the problems. I didn't have room for the machine and little time from working two jobs. I had to solve at least one of the problems right away...so I quit my primary job as a machinist of plastics making $25/hr plus bennies. That felt really good...no more getting up at 6am. Of course no more biweekly decent paychecks either.

I moved the manual turret lathe and honing machine into my storage container and was surprised to find I might have room after all.

So we made arrangements for my friend to pick up the machine and store it for awhile so I could get the garage ready. We were leaving on our first vacation in years for a week in Tahoe and then to the Bay area(Santa Cruz) to visit family. He was to follow me on the morning we were leaving, going the back way to Tahoe so we could stop at Central Oregon. Truck broke down on they way. Guy with machine was cool about it and we would handle it after returning.

While we were gone, we decided to get married so now I have a wife.

Upon returning, our boss from my part time job(my wife is a welder fabricator and works with me at the other job)decided to have us be full time, between the two of us, about three times the money from the job shop, but now back to super busy. Now the guy is starting to call wondering when the machine will leave and the rest of the money arrive, so I make arrangements right before Xmas to try again, this time the turbo blows on the way over the mountains. Ughhh.

So I let my friend off the hook, and call a different friend, but this one can't store it, so I have to bring it home. Also, when I told the machine owner we were on the road, he moved the machine outside so we could load it easier....needless to say, now the machine is outside in the winter under a tarp. Ughhh again...and a big storm is coming that will make it over the cascades. Ughhh some more.

I didn't have a choice but to wait out the storm and let the roads clear of snow, but we finally went and got it last week, and it went without a hitch other than not enough forklift, so I had to bring my millwright skills out of mothballs and figure out how to get it on the trailer. It wasn't fun but we succeeded with a block and tackle, lubricant, winches and come alongs.

Bringing it home we had a larger forklift available but only two inches clearance to the garage door. It took some fiddling with forlift forks and pallet jack, but we got it into the garage in a nice spot for me to work.

The machine is a 1991 Kira/Tree CNC mill with 10 tool positions. 5hp spindle, 787"/min rapids, 350"/min milling. Rigid Tapping, chip auger, Fanuc OM Mate control. It is more than fast enough for the work I do, and looks to be well designed and built.

The machine came with 86 tool holders of which 80% of them look to be in perfect shape, and the rest in reasonable shape.

I was able to buy a like new 20hp RPC from a friend for $1000 to get it running.

There are a couple of questions I have about it though, and am hoping someone here can enlighten me.

Here are some pictures, I will ask the questions at the bottom of the post.

I have three questions:

First: In the book it shows 12000rpm spindle, then refers to torque curves for three speed ranges. 0-4000, 0-8000, and 0-12000rpm. there does not seem to be any indication that these were options for the spindle, so...does that mean they simply have different control settings to create different speed and torque ratings for the spindle? Or do I misunderstand and there are three separate spindle options?

Second: The mill table is in wonderful shape and looks to have never been crashed into...however, it is a cross slot with eight mounting holes for fixture plates. The machine came with a nice fixture plate with dowel pins. Is there a company that makes reasonably priced custom T slot tables that could be bolted to the mill table?

Third: Anybody run or own one of these and have any possible tips or hints about running this machine?

Thank you all for your time and the many years of great and valuable info I have gleaned from Practical Machinist. And sorry bout the long post and diatribe.

Karl

Portland, Oregon

Last edited: