K Battenbough

Cast Iron

- Joined

- Aug 21, 2005

- Location

- Swansea, South Wales

Hello All

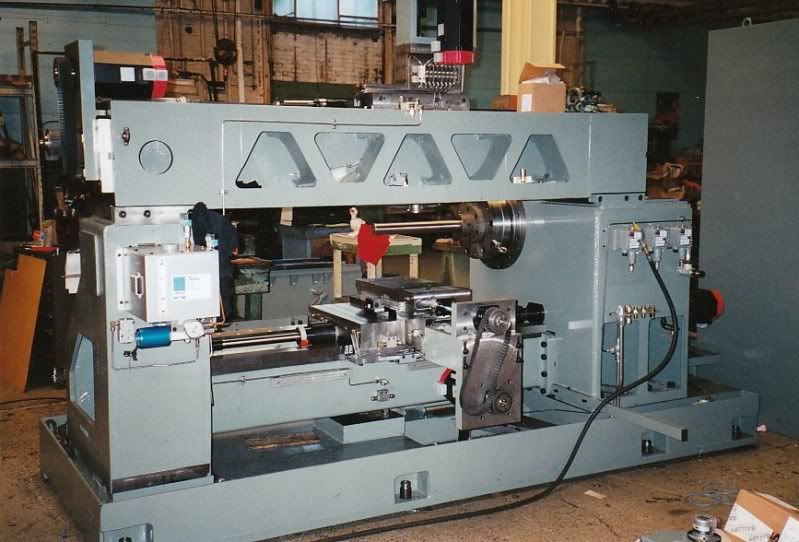

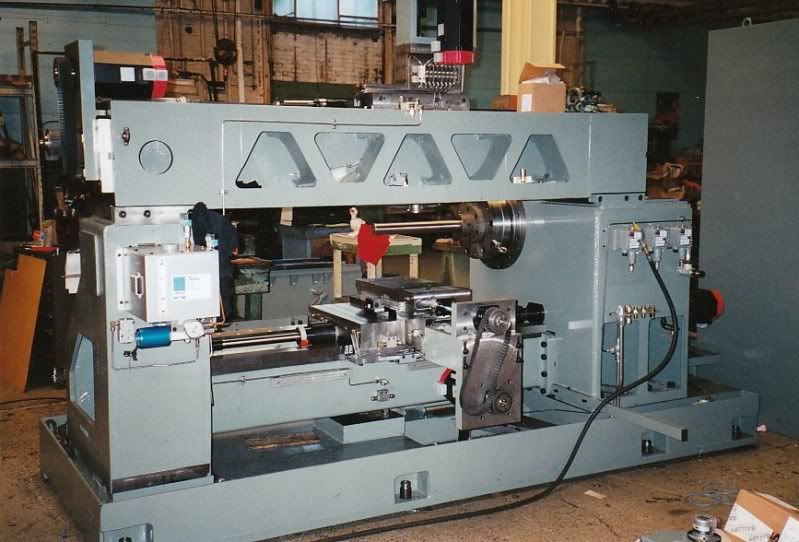

Just a simple question realy, I found these pics on the web and it got me thinking as to why we dont see more lathes setup this way? and more in favour of the slant bed? Is it purley a space saving issue, the only other possible problem I could think of would be over hang and weight of the tool turret?

Regards

KB

Just a simple question realy, I found these pics on the web and it got me thinking as to why we dont see more lathes setup this way? and more in favour of the slant bed? Is it purley a space saving issue, the only other possible problem I could think of would be over hang and weight of the tool turret?

Regards

KB